External shaft process package introduction#

In robot applications, it is sometimes necessary to extend the degree of freedom of the robot through the external axis, or to change the pose of the workpiece through the external axis. These extended degrees of freedom, either individually controlled, or need to be linked with the robot, at this time you need to use the external axis process package, let the robot control the external axis, to achieve better control effect.

Adaptation description#

Before the installation of the external shaft process package, it is necessary to ensure that the software version of the robot is suitable and the communication mode of the driver of the external shaft is specific:

Robot control software version |

V3.1.0 and above |

External shaft motor driver communication |

EtherCAT slave station,supports 4ms synchronous position mode |

You can query the version information of the robot on the About interface after the robot is powered on. For how to open the “About” interface, see Section 7 of the DUCO CORE- User Manual.

The driver compatibility of the external shaft must be confirmed by contacting the external shaft supplier.

The current version supports the following drive models:

Motor manufacturer |

Driver type |

Communication protocol |

|---|---|---|

Huichuan |

SV630N |

EtherCAT |

Inwiton |

DA200 |

EtherCAT |

Because EtherCAT communication needs topological adaptation, if there is a new type of motor that needs adaptation, it is necessary to contact the R & D department and provide the driver xml and sample for configuration.

Driver communication configuration#

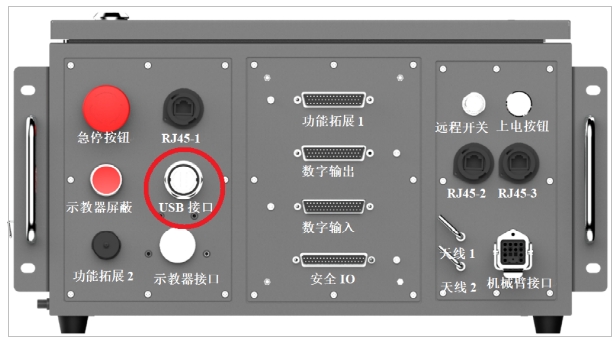

When using an external shaft for EtherCAT communication with the robot, refer to the collaborative robot User Manual (Hardware Part), and connect the EtherCAT port of the robot control cabinet to the EtherCAT_in port of the external shaft driver with a network cable.

After the network connection is complete, import the topology file of the corresponding drive to the robot by referring to the topology management chapter of the collaborative robot User Manual (Software Part).

Process package installation and uninstallation#

The external axis process package file is a plug-in of “eaxis.plugin”. The installation procedure is as follows:

1、put the external shaft process package into the U disk, U disk requires FAT32 format

2、 After the robot system is started, insert a U disk into the USB interface on the robot control cabinet.

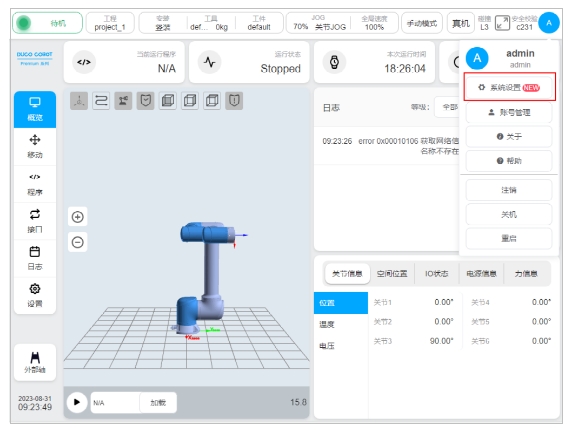

3、Log in to the robot system as user admin.

4、 Click the user profile picture and select System Settings.

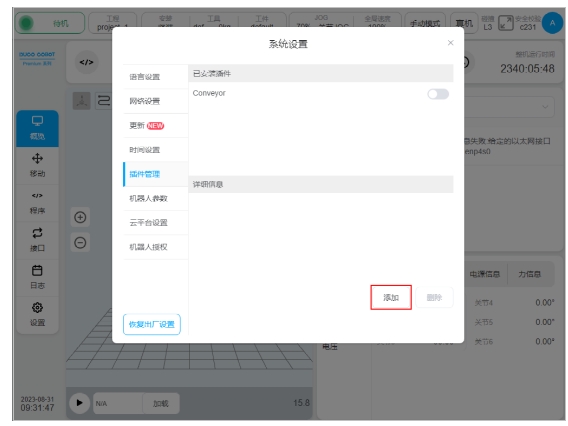

5、 Select the plug-in management function.

6、 Click the Add button.

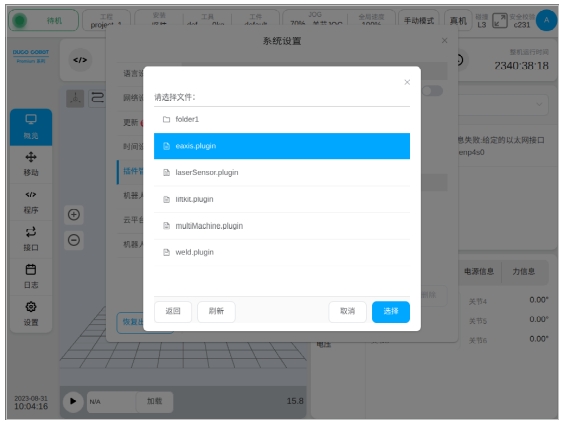

7、 select the USB flash drive and from the file list, find and select the “eaxis.plugin” plug-in package.

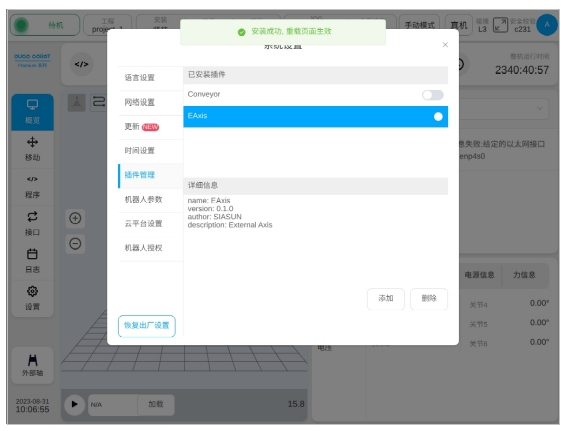

8、After the plug-in package is installed, as shown in the above figure, a box will be displayed at the top of the page indicating that the plug-in package is successfully installed and the reload page takes effect. Select the installed plug-in “Eaxis”, the details at the bottom of the page will display the name and version information of the current plug-in package.

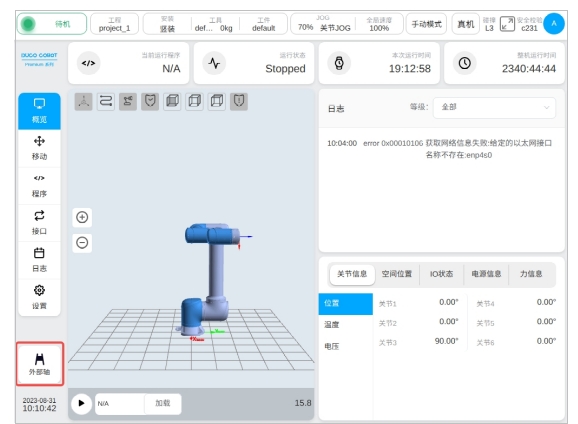

9、 After the installation of the external shaft process package is completed, the process package configuration entry will appear at the lower left of the main page.

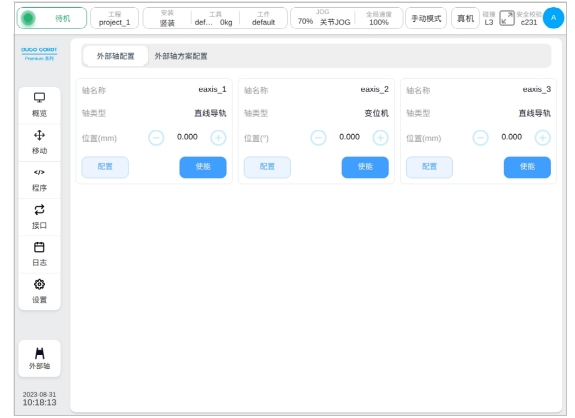

10、 Click the process package configuration entry button to enter the external axis process package configuration page.

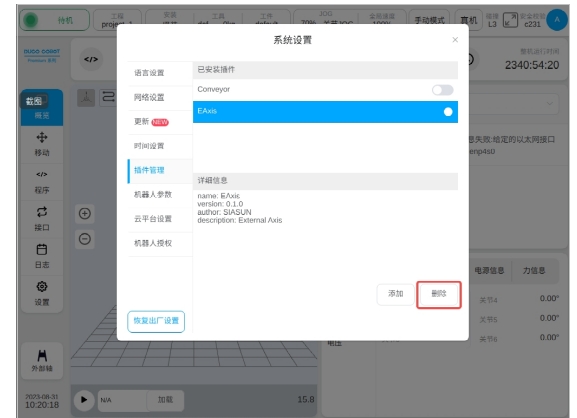

11、 The installed external shaft process package can be completely deleted by clicking the delete button on the plug-in management page.