Error Codes#

Error Message Window#

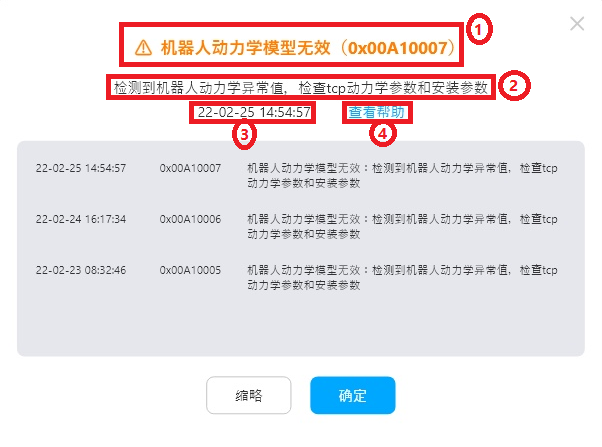

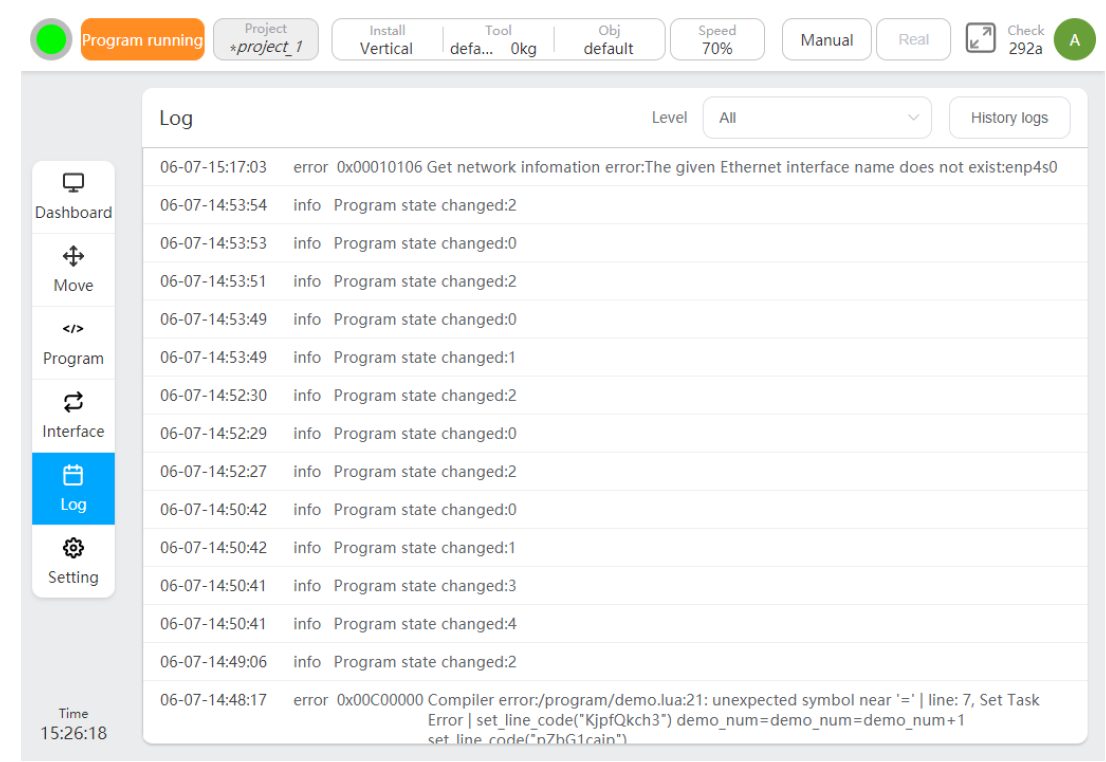

When an error log occurs, a pop-up window will be displayed on the interface at the same time to remind the users. Users can approximately understand the cause and handling methods of the error message through the pop-up window. The form of the pop-up error message window is shown in the following figure:

The first line of the pop-up window is marked with yellow bold characters to identify the error content and the corresponding error code.

The second line describes the cause of the error and the general direction of troubleshooting.

The third line records the time when the error occurred.

If you still have questions about the error, click “View Help” to learn more.

Error Code Composition#

The error code is composed of a set of hexadecimal 32-bit error codes, expressed in the form of 8-bit reservation bit + 8-bit error module id+ detailed error id. Take the invalid error 0x00A10007 robot dynamics model as an example:

Reservation Bit |

Error Module id |

Detailed Error id |

|---|---|---|

0x00 |

A1 |

0007 |

Error Code Table#

System issues[0x00]#

0x00000001: Robot power on error

Detailed description of the error |

Handle advice |

|---|---|

Fatal communication error detected |

Restart the control cabinet and contact developer if the error cannot be eliminated |

Safety board state in INIT |

|

Safety board version need to be updated |

Use the DucoCore upgrade function to upgrade the safety board to the minimum version required for version compatibility |

Get safety board version info fail |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet, Restart the control cabinet |

Get communicaiton board version info fail |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet,Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

IO board version need to be updated |

Use the DucoCore upgrade function to upgrade the communication board to the minimum version required for version compatibility |

Safety controller not in operational status |

Observe the switching process of the safety state machine in the dashboard page,record the state machine to which the safety controller was switched to the last before power-on, restart the control cabinet, and replace the safety board if the error cannot be eliminated, and check the internal problems of the replaced safety board |

Model parameters config fail 0x******** |

The communication layer is abnormal, record the communication error code, check the line between the controller and the safety board in the control cabinet, Restart the control cabinet |

Model parameters check error 0x******** |

|

Model parameters check timeout |

|

Safety power on fail 0x******** |

|

Record and query the safety board code and restart the control cabinet |

|

Safety stop1 triggered please restore |

Check whether the emergency stop of the teach pendant, the emergency stop of the control cabinet, and the emergency stop of the user are pressed and not reset, and power on again after resetting |

Safety power feedback abnormal |

Restart the control cabinet, if the error cannot be eliminated, check the status of the safety board and the power-on circuit in the control cabinet |

Switch communication frame to ready-to-switch-on status fail |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet,Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet, If the error cannot be eliminated, contact developer |

Communication frame swtich to swtiched-on status fail |

The communication layer is abnormal, usually caused by some slave abnormalities during the power-up process. Step 1: check the line between the controller and the safety board in the control cabinet,and check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), check the line between the control cabinet and the robot, check the internal power supply and communication wiring in the robot, and restart the control cabinet. Step 2: Check whether there is a process that has updated the robot system or updated part of the driver board,and there has been an update process exception.If so, contact developer to obtain the corresponding repair update package and re-update the interrupted system update. If the problem cannot be repaired after the above troubleshooting steps, contact developer. |

Switch communication frame to pre-operational status fail |

The communication layer is abnormal, the error is a fatal initialization error, If so, please contact developer directly for assistance |

Initialize communication frame fail |

|

Communication frame not in ready-to-switch-on status |

The communication layer is abnormal, usually caused by the abnormal connection between the safety board and the communication board in the control cabinet, check the line between the controller and the safety board in the control cabinet,and check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet) ,Restart the control cabinet, If the error cannot be eliminated, contact developer |

Servo version upload error |

Check the status and wiring of the servo drive board in the robot, and restart the control cabinet |

Servo version need to be updated |

It is recommended(not mandatory)to upgrade the servo drive to the minimum uniform version required for version compatibility by the DucoCore upgrade feature |

Get tcp board version info fail |

The communication layer is abnormal, check the wiring of the end board of the robot and restart the control cabinet |

Robot info check error |

|

Robot info and safety function parameters need to be updated |

Switch to an account with admin permissions, power on again, and synchronize the parameters stored in the end board of the robot to the control cabinet according to the pop-up window guidance, Restart the control cabinet |

Robot info need to be updated |

Switch to an account with admin permissions, power on again, and synchronize the parameters stored in the end board of the robot to the control cabinet according to the pop-up window guidance, Restart the control cabinet |

Toolboard config fail 0x******** |

The communication layer is abnormal, check the wiring of the end board of the robot and restart the control cabinet |

IO board config fail 0x******** |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet,Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

Safety parameters check error,Safety function parameters need to be updated 0x******** |

|

Safety function parameters need to be updated |

Reconfigure the safety parameters after the robot is powered off |

Axis config fail 0x******** |

The communication layer is abnormal, check the status and wiring of the servo drive in the robot. Restart the control cabinet |

0x00000002: Robot power off error

Detailed description of the error |

Handle advice |

|---|---|

0x00000003: Robot enable failed

Detailed description of the error |

Handle advice |

|---|---|

Brake deactive detected,please activate all brakes before enable operation |

By manually releasing the brake function to confirm that all joint brakes are closed and then re-enabled |

Safety state in * |

Record the abnormal safety controller status and restart the control cabinet. If the error cannot be eliminated, contact developer |

Axis * error detected 0x******** |

Record the servo error code and refer to the servo error checklist for troubleshooting |

0x00000004: Robot disable failed

Detailed description of the error |

Handle advice |

|---|---|

0x00000005: System reset failed

Detailed description of the error |

Handle advice |

|---|---|

Check whether the emergency stop signal is reset |

0x00000006: System shutdown failed

Detailed description of the error |

Handle advice |

|---|---|

Save the project |

0x00000007: System restart failed

Detailed description of the error |

Handle advice |

|---|---|

Check the shutdown failure cause |

0x00000009: Unregistered task or queue is full

Detailed description of the error |

Handle advice |

|---|---|

1.Restart the control cabinet;2.Check the programming logic |

0x0000000A: Task resume fail

Detailed description of the error |

Handle advice |

|---|---|

Please remove the current collision state |

Eliminate collision states |

File system issues[0x01]#

0x00010001: Add account failed

Detailed description of the error |

Handle advice |

|---|---|

The same account exist |

Change the name of your new account |

0x00010002: Delete account failed

Detailed description of the error |

Handle advice |

|---|---|

Account does not exist |

Confirm your account information |

0x00010003: Change password failed

Detailed description of the error |

Handle advice |

|---|---|

Wrong account number or password |

Confirm your account and password |

0x00010004: Login failed

Detailed description of the error |

Handle advice |

|---|---|

Wrong account number or password |

Confirm your account and password |

0x00010005: Check password failed

Detailed description of the error |

Handle advice |

|---|---|

Wrong account number or password |

Confirm your account and password |

0x00010006: Logout failed

Detailed description of the error |

Handle advice |

|---|---|

none |

— |

0x00010007: Verify Login failed

Detailed description of the error |

Handle advice |

|---|---|

Wrong account number or password |

Confirm your account and password |

0x00010008: Get account list failed

Detailed description of the error |

Handle advice |

|---|---|

File serialization failed |

Restart the control cabinet |

0x00010101: Load system file failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Restart the control cabinet |

0x00010102: Switch project failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Restart the control cabinet |

0x00010103: Set language failed

Detailed description of the error |

Handle advice |

|---|---|

none |

— |

0x00010104: Change wlan failed

Detailed description of the error |

Handle advice |

|---|---|

wifi.config open failed |

Check the Wifi module |

0x00010105: Change ip failed

Detailed description of the error |

Handle advice |

|---|---|

ifconfig failed(system) |

|

0x00010106: Get network infomation by name failed

Detailed description of the error |

Handle advice |

|---|---|

The given Ethernet interface does not exist:name |

1.Check the network name;2.Check the network card |

0x00010201: Add project failed

Detailed description of the error |

Handle advice |

|---|---|

The same project exists |

Change the project name |

Add folder failed:name |

0x00010202: Delete project failed

Detailed description of the error |

Handle advice |

|---|---|

Project not exist |

Confirm the project name |

0x00010203: Delete project failed

Detailed description of the error |

Handle advice |

|---|---|

Delete folder failed:name |

Confirm the project name |

0x00010204: Get projetct list failed

Detailed description of the error |

Handle advice |

|---|---|

Load folder failed:project |

The file system is damaged, please contact after-sales |

0x00010205: Rename project failed

Detailed description of the error |

Handle advice |

|---|---|

project not exist/Rename folder failed:A to B |

Confirm the project name |

0x00010206: Export project failed

Detailed description of the error |

Handle advice |

|---|---|

Compress file failed:name |

|

0x00010207: Import project failed

Detailed description of the error |

Handle advice |

|---|---|

Compress file failed:name |

|

0x00010301: Init filesystem failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Restart the control cabinet |

0x00010302: Save project failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Restart the control cabinet |

0x00010303: Get root file path failed

Detailed description of the error |

Handle advice |

|---|---|

Root is empty |

Restart the control cabinet |

0x00010401: Load project setting failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Restart the control cabinet |

0x00010402: Config function digital input failed

Detailed description of the error |

Handle advice |

|---|---|

none |

|

0x00010403: Config function digital output failed

Detailed description of the error |

Handle advice |

|---|---|

none |

|

0x00010404: Config function register input failed

Detailed description of the error |

Handle advice |

|---|---|

none |

|

0x00010405: Config function register output failed

Detailed description of the error |

Handle advice |

|---|---|

none |

|

0x00010406: Config interface name failed

Detailed description of the error |

Handle advice |

|---|---|

none |

|

0x00010407: Set current loaded program failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Check the setting information |

0x00010408: Set home position failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Check the home position of the setting |

0x00010409: Set project auto login failed

Detailed description of the error |

Handle advice |

|---|---|

none |

— |

0x0001040A: Set project default program failed

Detailed description of the error |

Handle advice |

|---|---|

none |

— |

0x0001040B: Change interface recipe failed

Detailed description of the error |

Handle advice |

|---|---|

File parse failed |

Rework the recipe |

0x0001040C: Open recipe failed

Detailed description of the error |

Handle advice |

|---|---|

Recipe type not match |

Check the recipe type |

0x0001040D: Create recipe failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Modify the recipe name |

0x0001040F: Delete recipe failed

Detailed description of the error |

Handle advice |

|---|---|

none |

1.Check the recipe name; 2.Stop the program from running |

0x00010410: Config profinet diconected response failed

Detailed description of the error |

Handle advice |

|---|---|

none |

Check the function output |

0x00010501: Load workcell error

0x00010502: Add TCP coordinate error

Detailed description of the error |

Handle advice |

|---|---|

The same TCP coordinate exists |

Change the tool coordinate name |

0x00010503: Modify TCP coordinate error

Detailed description of the error |

Handle advice |

|---|---|

Tcp not exist |

Check the tool coordinate name |

0x00010504: Delete TCP coordinate error

Detailed description of the error |

Handle advice |

|---|---|

Tcp not exist |

Check the tool coordinate name |

0x00010505: Add user coordinate error

Detailed description of the error |

Handle advice |

|---|---|

The same user coordinate exist |

Change the user coordinate name |

0x00010506: Modify user coodinate error

Detailed description of the error |

Handle advice |

|---|---|

User coodinate not exist |

Check the user coordinate name |

0x00010507: Delete user coodinate error

Detailed description of the error |

Handle advice |

|---|---|

User coodinate not exist |

Check the user coordinate name |

0x00010508: Set default tcp coodinater failed

Detailed description of the error |

Handle advice |

|---|---|

none |

0x00010509: Set default user coodinater failed

Detailed description of the error |

Handle advice |

|---|---|

none |

0x0001050A: Set robot installation failed

Detailed description of the error |

Handle advice |

|---|---|

none |

0x0001050B: Can not find world

Detailed description of the error |

Handle advice |

|---|---|

none |

0x0001050C: Can not find base

Detailed description of the error |

Handle advice |

|---|---|

none |

0x0001050D: Add model error

Detailed description of the error |

Handle advice |

|---|---|

Model with the same name already exists |

0x000163: Delete frame error

Detailed description of the error |

Handle advice |

|---|---|

Frame does not exist |

0x00010601: Load device file failed

Detailed description of the error |

Handle advice |

|---|---|

none |

1.Resync device information; 2.Restore the system to factory settings; 3.Contact after-sales |

0x00010701: Load safety filed failed

Detailed description of the error |

Handle advice |

|---|---|

none |

1.Resynchronize safety parameters; 2.Restore the default settings of safety parameters; 3.Contact after-sales |

0x00010801: Load logfile list failed

Detailed description of the error |

Handle advice |

|---|---|

Open log folder failed |

1.Reopen the log after shutting down and restarting; 2.Contact after-sales |

0x00010802: Load logfile failed

Detailed description of the error |

Handle advice |

|---|---|

Open file failed |

1.Reopen the log after shutting down and restarting; 2.Contact after-sales |

0x00010803: Export logfile failed

Detailed description of the error |

Handle advice |

|---|---|

Compress file failed |

1.Re-export the log after shutting down and restarting; 2.Contact after-sales |

0x00010901: Add global variable failed

Detailed description of the error |

Handle advice |

|---|---|

The same global variable exist |

Change the variable name |

0x00010902: Set global varialbe init value failed

Detailed description of the error |

Handle advice |

|---|---|

Value not exist or type not match |

1.Check the name of the global variable; 2.Check the input value type and the global variable type |

0x00010903: Delete global variable failed

Detailed description of the error |

Handle advice |

|---|---|

Value not exist |

Check the name of the global variable |

0x00010904: Get global variable list failed

Detailed description of the error |

Handle advice |

|---|---|

File serialization failed |

Restart the control cabinet |

0x00010A01: Set register value failed

Detailed description of the error |

Handle advice |

|---|---|

none |

1.Check the register address; 2.Check the input value type and register type; 3.Check the input values |

0x00010B01: Load directory list failed

Detailed description of the error |

Handle advice |

|---|---|

open name folder failed |

The FAT32 format flash drive needs to be replaced |

0x00010B02: Create directory failed

Detailed description of the error |

Handle advice |

|---|---|

:name |

Check whether the USB flash drive is in poor contact |

0x00010B03: Copy file failed

Detailed description of the error |

Handle advice |

|---|---|

A to B |

1.Modify the file name; 3.Check whether the USB flash drive is in poor contact |

0x00010B04: Delete file failed

Detailed description of the error |

Handle advice |

|---|---|

name |

1.Modify the file name; 3.Check whether the USB flash drive is in poor contact |

0x00010B05: Save file failed

Detailed description of the error |

Handle advice |

|---|---|

name |

1.Modify the file name; 3.Check whether the USB flash drive is in poor contact |

0x00010B06: Load file failed

Detailed description of the error |

Handle advice |

|---|---|

name |

1.Modify the file name; 3.Check whether the USB flash drive is in poor contact |

0x00010B07: File parse failed

Detailed description of the error |

Handle advice |

|---|---|

A to B |

1.Check the integrity of the documents; 2.Check the file format |

0x00010B08: Export directory error

Detailed description of the error |

Handle advice |

|---|---|

Compress file fail |

Try exporting again |

0x00010B09: append file error

Detailed description of the error |

Handle advice |

|---|---|

name |

1.Check the folder name; 2.Check whether the USB flash drive is in poor contact |

0x00010C01: Load motion para file failed

Detailed description of the error |

Handle advice |

|---|---|

Resynchronize robot parameters |

0x00010D01: Install plugin failed

Detailed description of the error |

Handle advice |

|---|---|

Confirm the completeness and correctness of the plug-in package |

0x00010D02: Uninstall plugin failed

Detailed description of the error |

Handle advice |

|---|---|

Confirm the completeness and correctness of the plug-in package |

0x00010E01:

Detailed description of the error |

Handle advice |

|---|---|

Confirm the completeness and correctness of the plug-in package |

Program issues[0x02]#

0x00020001: Run program failed

Detailed description of the error |

Handle advice |

|---|---|

Stop the running program |

0x00020002: Delete program folder failed;Types do not match

Detailed description of the error |

Handle advice |

|---|---|

Confirm the folder name |

0x00020003: Rename progarm folder failed;Types do not match

Detailed description of the error |

Handle advice |

|---|---|

Change the folder name |

0x00020004: Record trajectory failed

0x00020005:

Detailed description of the error |

Handle advice |

|---|---|

Confirm the name of the trajectory to be stopped |

0x00020006: Load progarm list failed

Detailed description of the error |

Handle advice |

|---|---|

Confirm the loading path |

0x00020007: Load progarm failed

Detailed description of the error |

Handle advice |

|---|---|

1.Confirm the loading path;2.Confirm the program name |

0x00020008: Save progarm failed

Detailed description of the error |

Handle advice |

|---|---|

Confirm the program name |

0x00020009: Delete progarm failed

Detailed description of the error |

Handle advice |

|---|---|

Confirm the program name |

0x0002000A: Rename Program failed

Detailed description of the error |

Handle advice |

|---|---|

Change the program name |

Movement issues[0x03]#

0x00030000: Move state queue fatal error

Detailed description of the error |

Handle advice |

|---|---|

Queue fault times over limit |

Contact develop |

0x00030000: Move kinematics calculation error

Detailed description of the error |

Handle advice |

|---|---|

0x******** |

Confirm the actual movement status of the robot and adjust the motion script |

0x00030000: Move task error

Detailed description of the error |

Handle advice |

|---|---|

Dual move task received |

Check whether there is a non-blocking motion called in the program and a new motion command is sent before the previous motion is completed (except for SpeedMove and ServoMove) |

0x00030000: Blend cancel

Detailed description of the error |

Handle advice |

|---|---|

code:0x******** |

Record fusion cancellation error code 0x********, Refer to the fusion motion programming technique process to modify the fusion motion parameters |

0x00030000: Move task aborted

Detailed description of the error |

Handle advice |

|---|---|

Receive invalid move task |

Confirm whether the current robot is in the program pause state, Check whether the motion task is sent through an external interface such as RPC.Stop the current running program and resend the motion task to confirm if the problem is gone |

0x00030001: Online move error

Detailed description of the error |

Handle advice |

|---|---|

Invalid velocity setting parameter |

Check whether the speed parameter is valid and modify the speed parameter |

0x00030002: Single move error

Detailed description of the error |

Handle advice |

|---|---|

Invalid velocity setting parameter |

Check whether the speed parameter is valid and modify the speed parameter |

Invalid acceleration setting parameter |

Check whether the acceleration parameter is valid and modify the acceleration parameter |

Invalid target pose parameter |

Check whether the target pose parameter is valid and modify the target pose parameter |

0x00030003: Blend move error

Detailed description of the error |

Handle advice |

|---|---|

Invalid blend radius setting parameter |

Check whether the fusion radius parameter is valid and modify the fusion radius parameter |

0x00030004: Spline move error

Detailed description of the error |

Handle advice |

|---|---|

The path input error |

Check whether there are two points in Spline programming where the spatial points coincide but there is a change in posture. Modify waypoint information |

Invalid velocity setting parameter |

Check whether the speed parameter is valid and modify the speed parameter |

0x00030005:

Detailed description of the error |

Handle advice |

|---|---|

0x00030006: Conveyor move error

Detailed description of the error |

Handle advice |

|---|---|

Conveyor move over limit 0x******** |

Check whether the current tracking limit distance is reasonable, Check whether the current conveyor speed and encoder value are abnormal. |

Robot conveyor sync fail 0x******** |

Check whether the current conveyor speed and encoder are abnormal, Check whether the current conveyor configuration parameters are reasonable |

0x00030007: Handling move error

Detailed description of the error |

Handle advice |

|---|---|

Unkonwn external force detected, check tcp load parameters |

Check that the current robot load mass and centroid parameters are filled in correctly, Check that the current robot installation orientation is set correctly, Check that there is no external force applied to the robot before the robot enters traction mode |

0x00030008: Teach replay error

Detailed description of the error |

Handle advice |

|---|---|

Current point is not same to replay starting point |

Confirm the starting point of the reproduction trajectory, and modify the robot script so that the robot is in this position before starting to pull the reproduction task |

The path input error |

Check whether there are two points in the traction reproduction teaching process where the spatial points coincide but there is a change in posture. Modify waypoint information |

Invalid velocity setting parameter |

Check whether the speed parameter is valid and modify the speed parameter |

0x00030009: Realtime control error

Detailed description of the error |

Handle advice |

|---|---|

Realtime communication lost |

Check the TCP communication wiring and its status |

Command joint position exceeds limit |

Check the real-time control joint position commands sent to the robot |

Command joint speed exceeds limit |

Check the real-time control joint position / joint velocity commands sent to the robot |

Command joint acceleration exceeds limit |

|

Command joint jerk exceeds limit |

|

Command joint torque exceeds limit |

Check the real-time control joint moment commands sent to the robot |

Command cartesian velocity exceeds limit |

Check the real-time control Cartesian position/Cartesian speed commands sent to the robot |

Command cartesian acceleration exceeds limit |

|

Command cartesian jerk exceeds limit |

|

Inverse kinematic position solve fail |

|

Inverse kinematic velocity solve fail |

|

Inverse kinematic acceleration solve fail |

|

Robot approaches singularity |

|

Command tool force exceeds limit |

Check the real-time control end force commands sent to the robot |

0x0003000A: Servo move error

Detailed description of the error |

Handle advice |

|---|---|

Inverse kinematic position solve fail |

Check the ServoMove command sent to the robot |

Forward kinematic position solve fail |

|

Robot approaches singularity |

0x0003000B: Brake test error

Detailed description of the error |

Handle advice |

|---|---|

Invalid test counter |

Confirm whether the joint is effectively displaced during the brake detection |

Brake operation error, 0x******** |

Communication layer problem, confirm the status and wiring of each joint of the robot, and restart the control cabinet |

0x0003000C: Dual robot calibration error

Detailed description of the error |

Handle advice |

|---|---|

Calibration calculation fail code: 0x******** |

Check whether the multi-machine collaboration function is started normally. Check whether the communication between the master and slave robot is normally connected,Check whether the calibration point position is coplanar, and record the calibration error code 0x******** |

0x0003000C: Sync Move Error

Detailed description of the error |

Handle advice |

|---|---|

Sync Move function is deactivated |

Check whether the multi-machine collaboration function is properly enabled in the settings page |

Illegle client sync move state |

Check whether the client robot is in a normal state. Check whether the communication between the master and slave robot is normally connected |

Illegle server sync move state |

Check whether the server robot is in a normal state.Check whether the communication between the master and slave robot is normally connected |

Fail to enter sync move |

Contact developer |

Sync move start position illegal |

Check whether the starting point of multi-machine cooperative motion is and the client robot respectively, and whether the robot is in the server robot in a singular configuration or exceeds the maximum spatial range, and modify the point |

Real-time control error |

Confirm the status of the master-slave robot, confirm whether the communication between the master and slave robot is normally connected, and confirm whether there is an error in the process of multi-machine cooperative movement |

Coordinate system issues[0x04]#

0x00040001: Set tcp coodinate failed

Detailed description of the error |

Handle advice |

|---|---|

Modify the tool coordinate system name |

0x00040002: Set user coodinate failed

Detailed description of the error |

Handle advice |

|---|---|

Modify the user coordinate system name |

0x00040003: Tcp calibration error

Detailed description of the error |

Handle advice |

|---|---|

Calibrate points are too close, The distance between any two points should be greater than 1 mm |

Re-teach the calibration point position to ensure that the distance between the points is greater than 1mm |

Unknown calibration type |

0x00040004: User Coordinate calibration error

Detailed description of the error |

Handle advice |

|---|---|

Calibrate points are too close, The distance between any two points should be greater than 1 mm |

Re-teach the calibration point position to ensure that the distance between the points is greater than 1mm |

Calibration points are collinear |

Manipulation mode issues[0x05]#

0x00050001: Switch operation mode error

Detailed description of the error |

Handle advice |

|---|---|

Operation timeout |

The safety board is abnormal, confirm the status of the safety board and restart the control cabinet |

0x00050002: Switch operation mode error

Detailed description of the error |

Handle advice |

|---|---|

Robot must in Enable state |

After the robot is enabled,switch the simulation mode |

Robot must in Stopped state |

Stop the current robot motion and the running script and switch the simulation mode |

IO port issues[0x06]#

0x00060001: Set digital output fail

Detailed description of the error |

Handle advice |

|---|---|

Confirm that whether the output port number is correct |

0x00060002: Get digtial input fail

Detailed description of the error |

Handle advice |

|---|---|

Confirm that whether the output port number is correct |

0x00060003: Set digital output failed

Detailed description of the error |

Handle advice |

|---|---|

io is configured with output function |

1.Confirm that whether the output port number is correct; 2.Confirm the current mode of the port |

0x00060004: Set digital output fail

Detailed description of the error |

Handle advice |

|---|---|

io is configured with output function |

Check whether the port is configured as a function output |

0x00060005: Set analog output mode fail

Detailed description of the error |

Handle advice |

|---|---|

Communication error 0x******** |

1.Confirm that whether the output port number is correct; 2.Confirm the current mode of the port |

0x00060006: Set analog input mode fail

Detailed description of the error |

Handle advice |

|---|---|

Communication error 0x******** |

1.Confirm that whether the output port number is correct; 2.Confirm the current mode of the port |

Safety setting issues[0x07]#

0x00070001: Safety controller switch to config mode fail

Detailed description of the error |

Handle advice |

|---|---|

Safety communication state not in OP |

Please disable and power off the robot first |

Operation timeout |

The safety board is abnormal, confirm the status of the safety board and restart the control cabinet |

0x00070002: Safety controller exit config mode error

Detailed description of the error |

Handle advice |

|---|---|

Safety in failure state |

The safety board is abnormal, confirm the status of the safety board and restart the control cabinet |

0x00070003: Set safety parameters tag error

Detailed description of the error |

Handle advice |

|---|---|

Operation timeout |

The safety board is abnormal, confirm the status of the safety board and restart the control cabinet |

0x00070004: Apply safety parameter error

Detailed description of the error |

Handle advice |

|---|---|

Operation timeout |

The safety board is abnormal, confirm the status of the safety board and restart the control cabinet |

0x00070005: Set safety parameters error

Detailed description of the error |

Handle advice |

|---|---|

Safety parameters download fail, 0x******** |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet, Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

Safety parameters upload fail, 0x******** |

|

Safety parameters crc check invalid, 0x******** |

The communication layer is abnormal, check the status of the safety board, check the line between the controller and the safety board in the control cabinet,Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

0x00070006: Abort set safety parameters error

Detailed description of the error |

Handle advice |

|---|---|

Operation timeout |

Restart the control cabinet |

Toolboard issues[0x08]#

0x00080001: Set toolboard digital output fail

Detailed description of the error |

Handle advice |

|---|---|

Confirm that whether the output port number is correct |

0x00080002: Set toolboard io mode error

Detailed description of the error |

Handle advice |

|---|---|

Mode parameter download fail |

1.Confirm that whether the output port number is correct; 2.Confirm the current mode of the port |

0x00080003: Config toolboard reuse interface error

Detailed description of the error |

Handle advice |

|---|---|

Port parameter download fail |

Confirm the current interface mode |

Baud rate parameter download fail |

0x00080004: Update toolboard firmware error

Detailed description of the error |

Handle advice |

|---|---|

Firmware upload fail |

1.Check whether the upgrade package is damaged. 2.Perform the upgrade operation again |

0x00080005: Change toolboard recipe failed

Detailed description of the error |

Handle advice |

|---|---|

Rework the recipe |

0x00080006: Config toolboard interface name failed

Detailed description of the error |

Handle advice |

|---|---|

1.Change the name; 2.Confirm the configured interface number |

0x00080007: Tool 485 write fail

Detailed description of the error |

Handle advice |

|---|---|

Occupied by real cycle or insert the queue fail |

Wait for the current task to complete |

0x00080008: Tool 485 read fail

Detailed description of the error |

Handle advice |

|---|---|

Occupied by real cycle or insert the queue fail |

Wait for the current task to complete |

0x00080009: Set tool led light brightness fail

Detailed description of the error |

Handle advice |

|---|---|

Configuration parameter write fail |

Confirm whether the end board of the current robot is damaged, Confirm whether the robot parameters are stored in the end board of the current robot, Confirm the status of the end board of the robot, Confirm the wiring of the end board of the robot, Restart the control cabinet |

Modbus communication issues[0x09]#

0x00090001: Add modbus device failed

Detailed description of the error |

Handle advice |

|---|---|

0x00090002: Delete modbus device failed

Detailed description of the error |

Handle advice |

|---|---|

0x00090003: Add modbus signal failed

Detailed description of the error |

Handle advice |

|---|---|

0x00090004: Delete Modbus signal failed

Detailed description of the error |

Handle advice |

|---|---|

0x00090005: Update modbus signal failed

Detailed description of the error |

Handle advice |

|---|---|

0x00090006: Write modbus value failed

Detailed description of the error |

Handle advice |

|---|---|

DataComm[0x0A]#

0x000A0001: Tcp socket open fail

Detailed description of the error |

Handle advice |

|---|---|

socket name already exist or socket num limit exceeded; socket open fail;socket open timeout |

1.Check whether there is a socket port with the same name open; 2.Check the socket |

0x000A0002: Tcp socket close fail

Detailed description of the error |

Handle advice |

|---|---|

close socket fail;socket name doesn’t exist |

Check whether the socket port is closed |

0x000A0003: Tcp socket write fail

Detailed description of the error |

Handle advice |

|---|---|

socket name doesn’t exist;socket write fail |

Confirm the name of the socket being operated |

0x000A0004: Tcp socket read fail

Detailed description of the error |

Handle advice |

|---|---|

socket name doesn’t exist |

Confirm the name of the socket being operated |

0x000A0005: 485 write fail

Detailed description of the error |

Handle advice |

|---|---|

in real cycle or insert the queue fail |

Wait for the current task to complete |

0x000A0006: 485 read fail

Detailed description of the error |

Handle advice |

|---|---|

in real cycle or already in use |

Wait for the current task to complete |

0x000A0007: CAN write fail

Detailed description of the error |

Handle advice |

|---|---|

in real cycle or data length incorrect |

Check whether the CAN configuration information is correct |

0x000A0008: CAN read fail

Detailed description of the error |

Handle advice |

|---|---|

in real cycle |

Check whether the CAN configuration information is correct |

Other issues[0x0F]#

0x00F00001: Synchronize robot parameter files fail

Detailed description of the error |

Handle advice |

|---|---|

Robot parameter files upload fail, 0x******** |

Confirm whether the end board of the current robot is damaged, Confirm whether the robot parameters are stored in the end board of the current robot,Confirm the status and wiring of the end board of the robot, and restart the control cabinet |

Robot parameter files download fail, 0x******** |

0x00F00002: Config encode interface fail

Detailed description of the error |

Handle advice |

|---|---|

IO board paramerter config fail, 0x******** |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet, Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

0x00F00003: Change baud rate fail

Detailed description of the error |

Handle advice |

|---|---|

Baud rate config fail, 0x******** |

The communication layer is abnormal, check the line between the controller and the safety board in the control cabinet, Check the line between the safety board and the communication board in the control cabinet(DC30 control cabinet), Restart the control cabinet |

0x00F00004: Update firmware fail

0x00F00005: Change can recipe fail

Detailed description of the error |

Handle advice |

|---|---|

file |

Rework the recipe |

0x00F00006: Change 485 recipe fail

Detailed description of the error |

Handle advice |

|---|---|

file |

Rework the recipe |

0x00F00007: Change socket recipe fail

Detailed description of the error |

Handle advice |

|---|---|

file |

Rework the recipe |

0x00F00008: Update robot software fail

0x00F00009: Brake control error

Detailed description of the error |

Handle advice |

|---|---|

Invalid target control mode |

Contact developer |

Brake operation interface error, 0x******** |

The communication layer is abnormal,Check the status and wiring of the servo drive board in the robot. Restart the control cabinet |

0x00F0000A: Kinematics calculation error

Detailed description of the error |

Handle advice |

|---|---|

0x******** |

Check the target point sent to the robot |

0x00F00010: Path length exceed limit

Detailed description of the error |

Handle advice |

|---|---|

0x******** |

Re-record the track point |

0x00F00020:

Detailed description of the error |

Handle advice |

|---|---|

Check whether the current robot model posture is consistent with the actual situation |

0x00F00021: Set servo parameter fail

Detailed description of the error |

Handle advice |

|---|---|

0x******** |

Record detailed error codes and feedback to the developer, Refer to the detailed error code information to troubleshoot communication exceptions |

0x00F00022: Apply servo parameter fail

Detailed description of the error |

Handle advice |

|---|---|

0x******** |

Record detailed error codes and feedback to the developer, Refer to the detailed error code information to troubleshoot communication exceptions |

0x00F00023: Path offser calculation error

Detailed description of the error |

Handle advice |

|---|---|

Invalid path type |

Check whether the path type parameter is correct in the corresponding script |

EtherCAT communication monitoring issues[0xA0]#

0x00A00001: Communication error

Detailed description of the error |

Handle advice |

|---|---|

code:0x13xxxxxx(busdevice error id) -0xxxxxxxxx(acontis error id) |

Record the BusDevice error ID and the ACONTIS error ID, Restart the control cabinet,and contact developer if the problem cannot be eliminated |

Safety function monitoring issues[0xA1]#

0x00A10000: Unknown joint movement detected during robot power off status

Detailed description of the error |

Handle advice |

|---|---|

Please verify current joint position accuracy |

Confirm whether the displayed position on the robot teach pendant model matches the real robot position, and continue to operate the robot after confirming that it is correct according to the prompts. If it does not match,it will be Power off, stop using and contact developer |

0x00A10001: Safety function violation detected

Detailed description of the error |

Handle advice |

|---|---|

Safety Error Description - 0x******** (Safety Error Code) |

For more information, please refer to the safety function error code, In view of the frequent speed safety problems, priority is given to safety monitoring errors due to speed fluctuations caused by robot vibrations, Try using the vibration control function as long as the site conditions allow |

0x00A10002:

Detailed description of the error |

Handle advice |

|---|---|

0x00A10003: Safety soft protection triggered

Detailed description of the error |

Handle advice |

|---|---|

Stop x triggered - protection message |

Check the trigger cause of the safety input, see safety function error code for details. If it is not a safety input trigger reason,In view of the frequent speed safety problems, priority is given to safety monitoring errors due to speed fluctuations caused by robot vibrations,Try using the vibration control function as long as the site conditions allow |

0x00A10004: Collision detection triggered

Detailed description of the error |

Handle advice |

|---|---|

Safety collision reaction triggered - Joint * / Robot tool / Robot base encountered a collision |

1.Check whether the robot collides with the outside world, Check whether the tools, dresspack and other factors have an impact on the normal operation of the robot, etc.; 2.Check whether the load mass and centroid parameters of setting are quite different from the actual working conditions; 3.Check whether there is a large deviation between the installation direction setting and the actual installation direction of the robot; 4.Check whether the brake is out of order. |

0x00A10005: Safety function parameters invalid

Detailed description of the error |

Handle advice |

|---|---|

Safety function parameters need to be updated |

Re-execute the process of configuring safety parameters |

0x00A10006: 3-position enable button loosen

Detailed description of the error |

Handle advice |

|---|---|

Stop 2 triggered - 3-position enable button need to be triggered to continue the operation |

Check whether the external three-position enable input is configured in the safety parameters,and if so,check whether the three-position enable is pressed normally |

0x00A10007: Need to carry out brake test

Detailed description of the error |

Handle advice |

|---|---|

Joint error monitoring issues[0xA2]#

0x00A20100: Axis 1 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 1 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

0x00A20200: Axis 2 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 2 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

0x00A20300: Axis 3 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 3 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

0x00A20200: Axis 4 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 4 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

0x00A20200: Axis 5 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 5 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

0x00A20200: Axis 6 status abnormal

Detailed description of the error |

Handle advice |

|---|---|

Axis 6 error detected, code:0x13xxxxxx(BusDevice error ID) -0xxxxxxxxx(Servo error ID) |

For more information, see Servo Error Codes |

Serial port data monitoring issues[0xA3]#

0x00A30001: Port parameters read error

Detailed description of the error |

Handle advice |

|---|---|

Cannot read serial port existing parameters |

Check the serial communication line inside the control cabinet |

0x00A30002: Set port parameters error

Detailed description of the error |

Handle advice |

|---|---|

Cannot set serial port parameters |

Check the serial communication line inside the control cabinet |

0x00A30101: Serial port open failed

Detailed description of the error |

Handle advice |

|---|---|

Serial port of power control board open failed |

Check the serial communication cable of the power management board inside the control cabinet |

0x00A30102: Abnormal communication detected

Detailed description of the error |

Handle advice |

|---|---|

Failed to send power control message/ power off message ….. |

Check the serial communication cable of the power management board inside the control cabinet |

0x00A30103: Abnormal communication detected

Detailed description of the error |

Handle advice |

|---|---|

Cannot receive the message from power control board |

Check the serial communication cable of the power management board inside the control cabinet |

0x00A30104: Power control board error

Detailed description of the error |

Handle advice |

|---|---|

Precharge resistor is overheated, please restart |

Let it sit for a while after shutting down |

0x00A30105: Power control board error

Detailed description of the error |

Handle advice |

|---|---|

Temperature of Power control board is too high, please restart |

Let it sit for a while after shutting down |

0x00A30106: Abnormal communication detected

Detailed description of the error |

Handle advice |

|---|---|

Failed to send restart message |

Check the serial communication cable of the power management board inside the control cabinet |

0x00A30201: Serial port open failed

Detailed description of the error |

Handle advice |

|---|---|

Serial port of teach pendant open failed |

Check the teach pendant wiring in the inside of the control cabinet |

0x00A30202: Manual movement is not allowed

Detailed description of the error |

Handle advice |

|---|---|

Teach pendent button disabled, robot need to be enabled |

Start the teach pendant button |

Websocket interface[0xB0]#

0x00B00001:

Detailed description of the error |

handle advice |

|---|---|

TCP/IP interface[0xB1]#

RPC interface[0xB2]#

Profinet interface[0xB3]#

Compilation issues[0xC0-0xC1]#

0x00C00000: compiler error

Detailed description of the error |

handle advice |

|---|---|

See error description |

Check the program logic |

0x00C10001: Task Parameter mismatch

Detailed description of the error |

handle advice |

|---|---|

task_name |

Confirm the Parameter correctness of task |

Servo Error Code#

Fault Detail |

Fault Cause |

Troubleshooting Method or Solution |

|

|---|---|---|---|

Comp atibility error |

(#99)C ompati bility Err |

The driver firmware version is too low. The firmware versions of CPU1 and CPU2 are incompatible. |

Suggestion: Upgrade the firmware versions of drives CPU1 and CPU2 to the latest version. |

Bus und ervoltage |

w0 Under_ voltag e_soft (0000 0001) |

Failure of the power supply itself |

Check whether the power output is proper. |

Insufficient power supply |

Check whether only one power supply is connected to the large-load control cabinet. |

||

Excessive speed or load (often accompanied by 20 hardware failures or 8000 current loop saturation failures) |

Check for excessive load and track speed. |

||

Driver device falling off Driver device welding error |

Exclude the above problems and try to replace the drive. |

||

Bus ov ervoltage |

w 1Over_ voltag e_soft (0000 0002) |

Power supply voltage fault |

Check whether the power supply voltage is within the operating range |

The brake board is not connected. |

Check whether the brake board is connected |

||

The hardware circuit of the overvoltage protection part is wrong. The driver device falls off or is welded incorrectly. |

Exclude the above problems and replace the drive. |

||

Overspeed |

w3Over _Speed (0000 0008) |

The ABS encoder is abnormal or the INC encoder is faulty |

Refer to Section 5.5 to check the corresponding sensor and harness according to ABS and INC error messages. |

Driver te mperature sensor fault |

w4IGB TTemp_ sensor _error (0000 0010) |

Thermistor missing or welding error. |

Replace the drive. |

Hardware ove rcurrent/ unde rvoltage/ ov ervoltage |

w5Ha rdware _error (0000 0020) |

The UVW is loose or in poor contact. |

If the current waveform sometimes changes to 0, check whether the UVW cable is secure. |

The INC connection sequence is reversed or the pulse is lost. |

Check whether the INC connection is correct, whether the code disk is scratched, and whether the installation is qualified; Refer to Section 5.5 to search for INC code loss. |

||

If 1 undervoltage or 8000 current ring saturation fault occurs at the same time during operation, the possible cause is that the bus voltage drops abnormally |

The oscilloscope observes whether the bus voltage is normal |

||

Incorrect parameters lead to current oscillation and overcurrent |

Confirm the servo parameters. |

||

After the upper computer detects the collision, the back-up acceleration instruction is too large. Excessive user trajectory acceleration and speed; |

Check the 1og file for collision detection at the same time. Check the parameter settings of user trajectories. |

||

The power supply is insufficient, and there is a problem with the current sharing module (for example, all joints of the whole arm report the fault at the same time) |

Replace the power supply or current balancing module. |

||

The driver board hardware faulty |

If the preceding information is normal, replace the drive. |

||

ABS encoder is abnormal. |

Refer to Section 5.5 to query the ABS status. |

||

Position error out of limit |

w6Pos i_Erro r_Over (0000 0040) |

The three-phase line sequence of the motor itself is reversed. |

Check whether the three-phase cable sequence of the motor is reversed. |

UVW tightening force is too strong, resulting in the fracture of the three-phase cable. |

Check whether the three-phase cable of the motor is broken. |

||

The INC wiring harness is reversed. The reading head code disk installation gap is problematic. The radial installation distance is problematic. The code disk is contaminated. |

Check INC encoders one by one (harness sequence, code disk, mounting distance, reading head). |

||

Driver board o verheated |

w7I GBT_Ov ertemp (0000 0080) |

The ambient temperature is too high or the thermistor is damaged. |

Stop running for a period of time. After the temperature drops, power on the driver and check whether the ambient temperature exceeds the threshold. If no, the ambient temperature exceeds the threshold |

Self-test failure |

w8Se lfTest (0000 0100) |

The power-on self-test of the driver board failed. |

Power off and restart. If the error is still reported, contact R & D. |

Ethernet comm unication overtime |

w9 No_Mot ionCMD (0000 0200) |

The ECAT network cable or connector terminal is damaged (for example, the buckle is damaged). |

Try to change the cable; Attempt to change the drive. |

If the communication is broken, the communication recovers by itself after cooling for a while: the power chip overtemperature causes the DSP to reset. |

Check whether the ambient temperature is too high. |

||

The communication is completely disconnected and can be restored after being powered on again: the communication module is overheated. |

Check whether the ambient temperature is too high. |

||

U-phase current sensor fault |

w10Cur rentu_ sensor _error (0000 0400) |

H ardware-related fault |

Replace the drive. |

Invalid ABS encoder data |

w 11ABS_ data_i nvalid (0000 0800) |

H ardware-related fault |

Refer to Section 5.5 and check the wiring harness and encoder according to the ABS error message; If nothing goes wrong, replace the drive. |

Bus voltage sensor fault |

w12Vo ltage_ sensor _error (0000 1000) |

The bus voltage sensing chip is not welded, welded incorrectly or damaged. |

Replace the drive. |

Abnormal ABS encoder c onnection |

w 13ABS_ lost_c onnect (0000 2000) |

ABS encoder harness contact is poor. |

Replace the ABS harness. |

The driver board connector is damaged or in poor contact |

Replace the drive board. |

||

Current sampling module fault |

w 14Curr _samp_ module _error (0000 4000) |

H ardware-related fault |

Replace the drive. |

Current loop s aturation fault |

w 15Satu ration (0000 8000) |

The current sharing module of the power cabinet is not connected, and the voltage drops due to insufficient power under high speed and acceleration conditions. |

Check whether only one power module is connected to the large-load cabinet. |

A phase of the motor is broken. |

Check whether the three-phase cable of the motor is tight. |

||

Instruction acc eleration/speed is too high. |

Check user trajectory parameter settings. |

||

The MOSFET is damaged or the current sampling chip is removed. |

Replace the drive. |

||

Hardware version error |

w16Har dwareV ersion (0001 0000) |

The hardware version number is not written or is incorrectly written. |

Return to incoming material inspection station for processing |

Motor overte mperature |

w18M otorOv erHeat (0004 0000) |

The electromagnet did not bounce off. |

Check whether the electromagnet bounces off. |

Command spe ed/acceleration is too large. |

Check the user trajectory. |

||

INC failure; Motor three-phase line sequence reverse; Parameter file error. |

Check INC code loss with reference to Section 5.5, check the motor three-phase line sequence, and confirm the parameter file. |

||

main control chip overheat |

w20 DSP_Ov erTemp (0010 0000) |

DSP overtemperature |

Ambient temperature is too high. |

Double encoder ca libration error |

w21Enc oderHa llCros sCheck (0020 0000) |

Incorrect reduction ratio setting of joint reducer, ABS or INC-related failure |

Reconfigure the joint deceleration ratio or check the deceleration model number, refer to Section 5.5 to troubleshoot the encoder problem and further target. |

ABS encoder CRC check error |

w22A BS_CRC _error (0040 0000) |

The ABS read head model is not matched, or the signal is interfered, or the servo parameters are incorrect |

Replace the wiring harness, ensure that the reading head is correct, and confirm the servo parameters. |

Near invalid ABS encoder data |

w 24ABS_ data_w arning (0100 0000) |

Hardware related |

Refer to Section 5.5 to identify the root cause. |

INC encoder pulse loss |

w25INC _error (0200 0000) |

The INC code disk is contaminated. |

Wipe the code tray if it is contaminated. |

There is a problem with INC installation. |

Use INC special detector test, if the same error, adjust the reading head axial/radial position, adjust the assembly of the code disc, adjust the gap between the reading head and the code disc. |

||

Loose connector |

The connector is glued and fixed. |

||

Driver hardware circuit error (push-down resistance not removed) |

Replace the drive board. |

||

There’s a problem with the harness |

Replace the harness. |

||

Driver board fault |

Exclude the preceding faults and replace the driver board. |

||

V phase current sensor fault |

w27Cur rentv_ sensor _error (0800 0000) |

H ardware-related fault |

Replace the drive. |

W phase current sensor fault |

w28Cur rentw_ sensor _error (1000 0000) |

H ardware-related fault |

Replace the drive. |

Phase finding failure |

w29Ha llLess _Doubl eCheck (2000 0000) |

INC harness sequence is incorrect. |

Check that whether the INC harness sequence is correct. |

The gap between INC read head and code disk is unqualified. |

Test to ensure compliance. |

||

The welded heads on the INC harness are bent causing reading problems. |

Replace the unbent harness. |

||

The three-phase UVW line of the motor itself is welded back. |

Adjust the UVW to the correct connection to the drive. |

||

Wrong parameter file |

Confirm the parameter file. |

||

INC encoder loss Z |

w30 INCnoZ (4000 0000) |

INC code disk design problems. |

Replace the correct INC code disk. |

INC disc radial mounting problem |

Reinstall the INC platter and read head, and control the motor radial runout. |

||

Elec tromagnet current overflow |

w31 BrakeO verCur (8000 0000) |

Voltage drop due to overtemperature or insufficient power supply |

The driver board recovers after power failure for a period of time, indicating that the temperature is the problem. Check whether the power supply is connected only one way or the user’s command track speed/acceleration is too large. |

Description of the Servo Error Message#

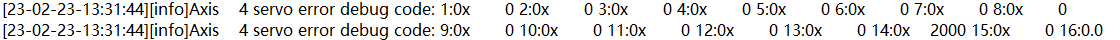

When a fault occurs, the controller of the robot arm will automatically query the internal fault word of each axis (provided that the robot arm is not powered off), and the detailed servo error information can be queried by exporting the log information, as shown in Figure 1.

Figure 1 Error information reported on each axis

Figure 1 Error information reported on each axis

The message meaning of the error code is as follows:

a) Values 1 to 10 indicate the error axis time. The first 10 hexadecimal numbers related to the INC encoder, whose specific meaning and order are as follows:

1)The pulse number automatically compensated by the firmware;

2)The pulse number increment between the last two Z pulses;

3)The pulse number increment between the first two Z pulses when the maximum code loss occurs;

4)The code corresponding to the last Z-pulse before the fault;

5)~9)The codes corresponding to the last 5 Z pulses (1 circle 0~FFFF);

10)The reference code corresponding to the Z pulse (1 circle 0~FFFF);

b) The values 11 to 15 are hexadecimal numbers. The corresponding meanings are as follows:

11)The maximum code loss value in history (read by the INC encoder) since the last cleaning fault or power-on;

12)ABS fault code;

13)Continuous current loop saturation time (within 100us) before servo fault alarm;

14)The historical fault LOG contains four digits higher information. (Read Section 5.4)

15)The historical fault LOG contains four digits lower information. (Read Section 5.4)

The value 16 is a decimal number with the following meanings:

16)The maximum number of consecutive EtherCAT frames lost since power-on (maximum 4);

Methods for Querying Joint Fault Information#

You can query joint fault information as follows:

INC encoder code loss information query

Taking Axis1 as an example (refer to 11 in Figure 1): The historical maximum code loss since the last cleanup or power-on is explained as follows:

Definition of reading: The historical maximum code loss value since the last fault clearance or last power-on;

Conversion method: Assume that the reading is M (converted decimal), INC coil number L; Then:

The angle corresponding to the code drop (°) = (M/65536) * 360;

The number of encoder pulses corresponding to code loss = (M/65536) * (L*4);

Note: (1) The INC code loss that results in complete loss of encoder pulse due to reading head damage and other reasons cannot be detected. (2) The detailed code loss information can be referred to records 1) ~10).

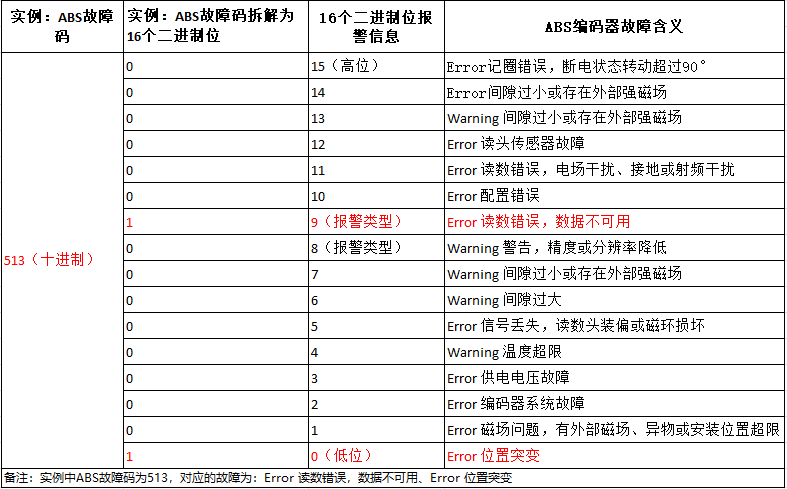

ABS encoder fault query

Taking Axis1 as an example (refer to Figure 1 12): ABS fault code, meaning all the fault bits that have occurred since power-on, and detailed alarm information and examples are shown in the following figure.

Current loop saturation duration query

Taking Axis1 as an example (refer to 13 in Figure 1): The current loop saturation time (within 100us) that occurs continuously before the servo fault alarm.

Historical fault LOG information query

1) High 4 bits of information: taking Axis1 as an example (refer to 14 in Figure 1);

2) Low 4 bits of information: taking Axis1 as an example (refer to 15 in Figure 1);

3) Combine the high and low information into an 8-digit hexadecimal number. You can view the fault information in the table. The fault information means all the faults (including the masked faults) that have occurred since the last fault clearance or last power-on;

4) Specific examples: read high message 0010 and low message 0020; Combine the high-bit and low-bit information into an 8-digit hexadecimal number 00100020. Check the table for the fault information: Hardware fault and DSP overtemperature.

Historical EtherCAT frame drop information query

Taking Axis1 as an example (refer to 16 in Figure 1): The number of consecutive frames (up to 4) that have been lost since power-on.

Figure 2 ABS error message

Error Message from Safety Controller#

Safety controller main status:

SS_INIT |

0 |

|---|---|

SS_WAIT |

2 |

SS_CONFIG |

3 |

SS_POWER_OFF |

4 |

SS_RUN |

5 |

SS_RECOVERY |

6 |

SS_STOP2 |

7 |

SS_STOP1 |

8 |

SS_STOP0 |

9 |

SS_MODEL |

10 |

SS_REDUCE |

12 |

SS_BOOT |

13 |

SS_FAIL |

14 |

SS_ARM_BOOT |

15 |

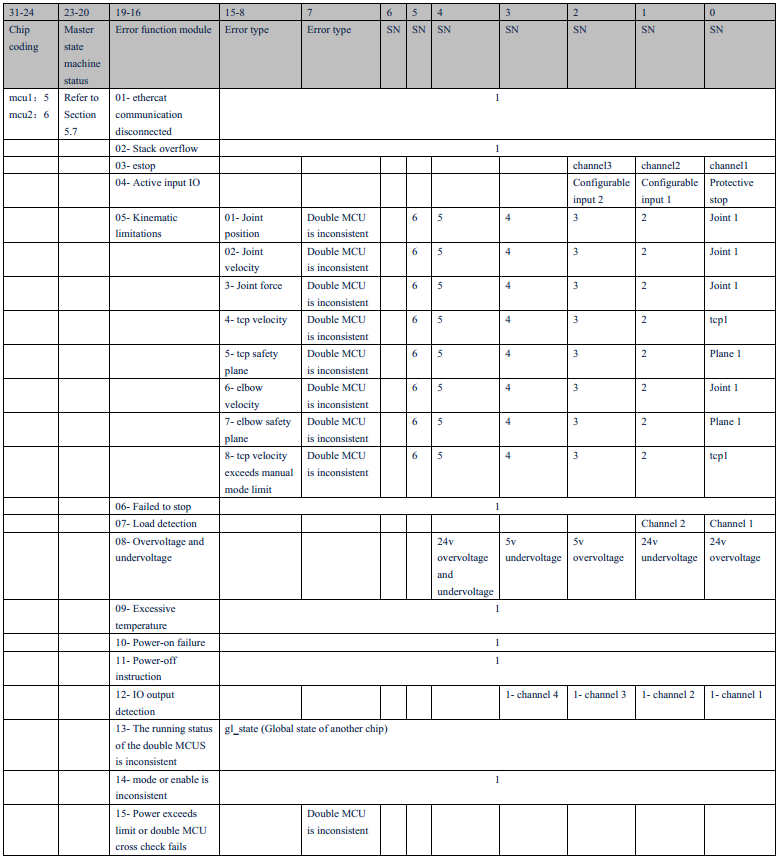

Error Code Table Reported by the Safety Controller#