Introduction to Belt Tracking#

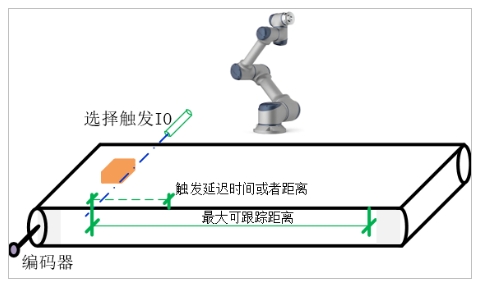

For the workpiece placed on the conveyor belt, the workpiece will move forward with the conveyor belt when the user chooses to use the conveyor belt tracking system, the robot TCP will automatically track the workpiece moving on the conveyor belt, and when the robot is in sync with the workpiece, the robot TCP speed will be maintained It is consistent with the speed of the conveyor belt and can withstand certain speed fluctuations of the conveyor belt.

Conveyor belt tracking system composition#

For the workpiece placed on the conveyor belt, the workpiece will move forward with the conveyor belt, when the user chooses to use the conveyor belt tracking system, the robot TCP will automatically track the workpiece moving on the conveyor belt, when the robot and the workpiece are in the synchronization stage, the robot TCP speed will be consistent with the conveyor belt speed, and can withstand a certain speed fluctuation of the conveyor belt.

encoder parameter Settings#

The robot conveyor encoder supports two types of AB and ABZ, which can be configured according to the actual situation. The configuration interface is in the interface interface, and the operation process is as follows: 1) Click the interface at 1, 2) click the CCI at 2, and 3) select the AB or ABZ at 3 according to the actual situation. When the encoder type is selected as ABZ, the user also needs to set the number of encoder lines, which is set by referring to the encoder instruction manual or consulting the encoder manufacturer.