Program Editing#

Adds motion directives#

The following takes the uniform speed linear conveyor belt as an example, briefly describes the conveyor belt tracking program editing process:

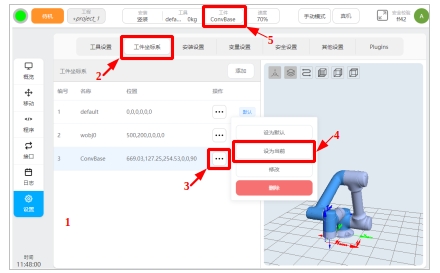

It should be noted that the coordinate system of motion instruction under the conveyor belt needs to be set to the coordinate system of the conveyor base, that is, the coordinate system calibrated in the previous section, ConvBase. Therefore, before the teaching point, it is necessary to set the workpiece coordinate system ConvBase to the current, click Set (1 place), click the workpiece coordinate system (2 place), select ConvBase and click (3 place), select current and click (4). After successful setting, you can check whether the current workpiece coordinate system has been changed to ConvBase in the workpiece coordinate system display (at 5). If it has been changed, it indicates that the setting is successful. If not, you need to repeat the above operation until it is successful.

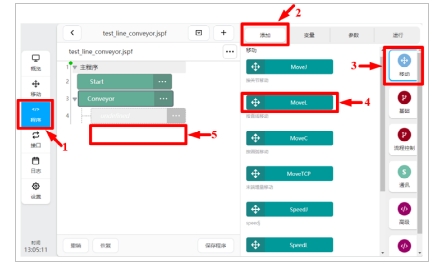

Now that the Conveyor belt tracking preparation is completed, the following can program the conveyor belt tracking, click the program (1) to return to the program editing interface, add button (2), select move (3), select MoveL(4), drag MoveL to the conveyor belt following node (5), complete the conveyor belt tracking instructions added.

According to the actual working conditions, the mobile robot will Move to the designated position, return to the program interface, select parameters, click the selection point, record the current position, and complete the parameter configuration of MOVE instruction. According to the actual working conditions, the Move command is repeatedly added and the corresponding point is taught, and the following sub-commands are added to complete the conveyor belt tracking. Current Move instructions supported by conveyor tracking include MoveJ (pose mode), MoveL, MoveC, and MoveTCP.

Program example#

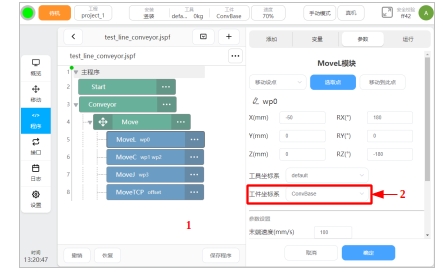

•Repeat the steps in 5.1 to add MoveL, MoveC, MoveJ(pose mode), and MoveTcp to the program tree (Figure 1 below). In particular, it should be noted that the workpiece coordinate system recorded in all instructions should be displayed as the conveyor base coordinate system (ConvBase in this case), otherwise the robot will not track the instruction, which is easy to cause unexpected results. If the workpiece coordinate system recorded by the program is not the conveyor belt base coordinate system, that is, the coordinate system at 2 in the figure below is not the conveyor belt base coordinate system, it is necessary to switch to the setting interface, and set the conveyor belt base coordinate system to the current, teach the point again, and confirm.