Application Cases#

Synchronous follow application cases#

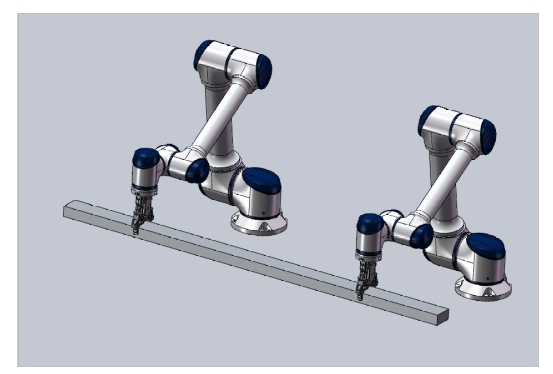

As shown in the figure, two robots are expected to grasp and place the same workpiece at the same time according to the state shown in the figure. Since the workpiece itself is long and the stiffness is large, two robots are required to complete the collaborative work with extremely high precision synchronization, so as to avoid the damage of the workpiece due to the large shear force caused by the non-synchronous movement between the two robots.

For the above conditions, multi-machine co-programming can be achieved in the following ways:

1、 Refer to Chapters 3 to 4 to complete the plug-in installation, communication connection debugging, master-slave configuration, master-slave calibration and function activation of the two robots;

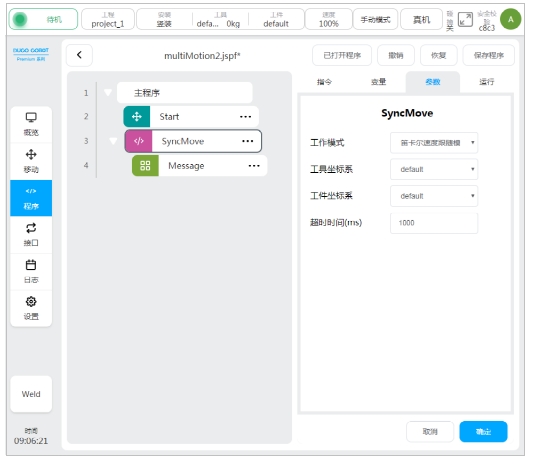

2、 Write the master robot script program, add the root node of SyncMove script at the starting point of grasping the workpiece, configure the parameters correctly, and add the required motion script for grasping and placing the workpiece under the root node. Because the actual working condition requires the master-slave robots to strictly maintain the synchronization of grasping speed in Cartesian space, so as to avoid generating shear force on the workpiece, the Cartesian speed following mode can be used. If the two robots are correctly configured with the tool and the workpiece coordinate system, so that the position of their respective tools in the workpiece coordinate system is always the same during the grasping process, the Cartesian position following mode can also be selected. As shown in the picture below:

3、 After completing the configuration of the master robot, the slave robot only needs to add the SycMove root node at the starting point of its workpiece grab and configure it, without adding any other instructions below it. As shown in the picture below:

Features follow application cases#

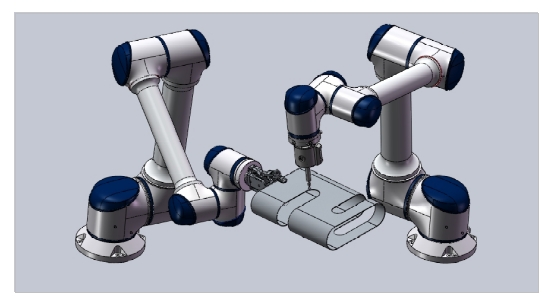

As shown in the figure, robot needs to process and polish the workpiece. However, due to the limitation of its space motion range due to its configuration, robot cannot effectively complete the processing of the complete workpiece surface. At this point, another robot is needed to grab the workpiece and move it so that the complete workpiece surface can be processed and polished by robot in its workspace to touch and complete the job.

For the above conditions, multi-machine co-programming can be achieved in the following ways:

1、 Refer to Chapters 3 to 4 to complete the plug-in installation, communication connection debugging, master-slave configuration, master-slave calibration and function activation of the two robots;

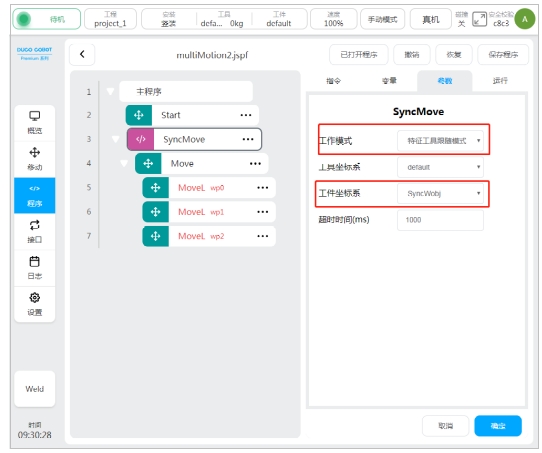

2、 The master robot acts as the workpiece grasping robot, and selects a feature point on the workpiece after capturing the workpiece as its tool coordinate system to write the motion script during SyncMove synchronous movement, as shown in the following figure:

3、From the robot as a working robot, the same feature point on the workpiece should be selected as its workpiece coordinate system, and the workpiece operation track should be taught in the workpiece coordinate system, and it should be added to the root node of SyncMove script. As shown in the picture below:

4、 When the master and slave robots enter the synchronization mode, the master and slave robots will start to execute motion commands by referring to the motion script under their respective SyncMove root node. In the synchronization process of the robot, the coordinate system of all the moving reference workpiece will be synchronized with the position of the tool coordinate system of the master robot, and the real-time correction of its own motion instructions, so as to achieve the goal of synchronous job processing.