Introduction#

Welding applications often require direct communication between the robot and the welder to reduce communication latency and thus achieve better weld quality.

Adaptation Instructions#

Before installing the Welding Process Package V2, you need to ensure that the robot’s software version is adapted, specifically:

Robot control software version |

V3.5.0 and up |

Robot Slave Firmware Versions |

V1.0.2 and up |

Robot Safety Controller Versions |

V2.1.0 and above |

The version information of the robot can be found in the About screen after powering up the robot. To open the “About” screen, see chapter 7 of the DUCO CORE User Manual.

Welding process packages of version V2.0 and above are required to ensure that the robot’s software version is V2.7.0 and above.

The welder models supported by the current version are:

Welder Manufacturers |

Welder Models |

Communication Protocols |

|---|---|---|

OATAI |

NBC-500RP Plus / NBC-350RL |

CAN |

Tongyong |

RB_P系列 |

CAN |

Megmeet |

CAN/DeviceNet |

|

WeldTec |

DeviceNet |

|

Headux |

DeviceNet |

|

Panasonic |

DeviceNet |

|

EWM |

DeviceNet |

|

WECO |

Modbus TCP |

|

Bingo |

CAN |

|

Kemppi |

Modbus TCP |

|

Soldamatic |

Modbus TCP |

|

Fronius |

DeviceNet |

|

Cloos |

DeviceNet |

Welder connection#

The welding power supply can choose digital communication and analog communication, and can be selected according to actual needs

Digital Type#

When using CAN communication, you need to refer to the Collaborative Robot User’s Manual (Hardware Section), and the welder’s manual, and interface the CAN communication interface of the two. Take the example of adapting Aotai NBC-500RP Plus / NBC-350RL series welding machine:

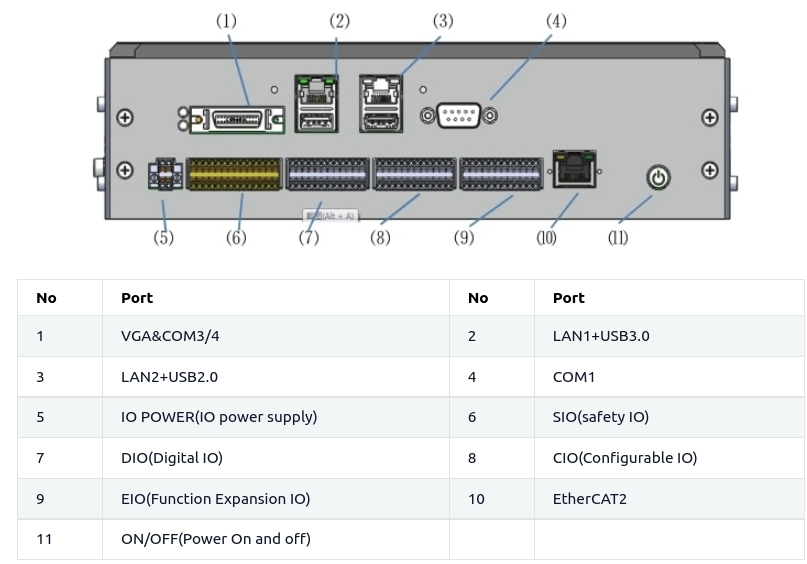

Check the Collaborative Robot User’s Manual (Hardware Section) to find the CAN communication interface, as shown below:

From the table, it is clear that CAN communication uses pins 11, 18, and 20.

Check the manual of the welder and find the CAN communication interface on the welder side, as shown in the following figure:

according to the instructions of the robot and the welding machine, connect the welding machine communication cable No. 2 to the corresponding line and the robot expansion interface pin 18.

No. 7 to the corresponding line and the robot to expand the interface pin 20, connect the No. 3/6 pin to the corresponding line to the robot expansion interface pin 11 to complete the wiring.

Analog Type#

Connection#

When the multi-cobot is connected to the welding power supply for analog communication, two sets of relays need to be configured, and the number of relay groups is selected according to the actual function. The specific wiring method is different according to the type of welding power port. The details are as follows:

When the welding power port type is PNP, the wiring mode is as follows:

When the soldering power port type is NPN, the wiring method is as follows:

The power supply of the welding machine is connected to the 0-10V analog voltage output interface (AO interface) of the robot controller given welding current and welding voltage

The actual current and actual voltage returned by the power supply of the welding machine are connected to the analog voltage input interface (AI interface) of the robot controller.

The following table describes the I/O correspondence table

Port Group |

Port |

Description |

DIO |

DI1(5) |

Start Arc success |

DI2(7) |

Welder Ready |

|

DI3(9) |

Touch success |

|

DO1(6) |

Start Arc |

|

DO2(8) |

Wire feed |

|

DO3(10) |

Wire back |

|

DO4(12) |

Gas Test |

|

DO5(14) |

Robot Ready |

|

DO6(16) |

Enable touch |

|

DO7(18) |

JOB1 |

|

DO8(20) |

JOB2 |

|

CIO |

DO9(6) |

JOB3 |

EIO |

AI1(1) |

Actual current |

AI2(3) |

Actual voltage |

|

AO1(5) |

Current |

|

AO2(7) |

Voltage |

Software Operation#

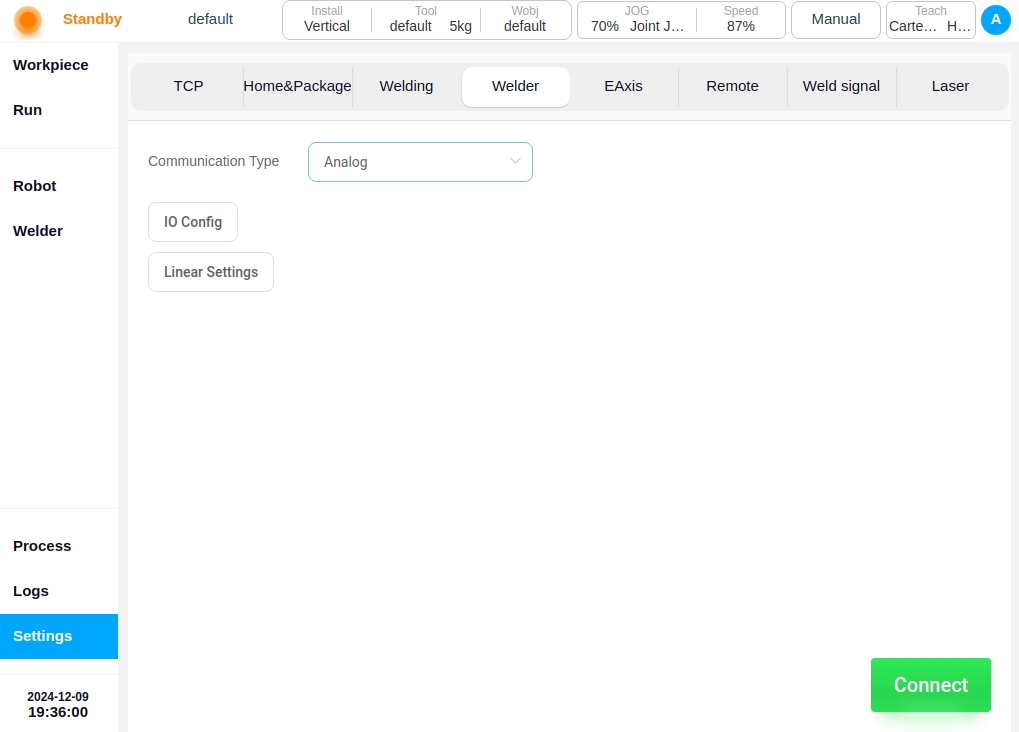

Enter the “Basic Settings” - “Welder Configuration” page, and select “Analog Communication” as the communication mode. Click the “Connect” button in the bottom right corner to take effect

Click “I/O Correspondence Table” to query the I/O signal correspondence status on the I/O Correspondence Table page

Click the “Linearization” setting, click the “Edit” button to set the correspondence between the welding current and voltage and the analog quantity

After the setting is completed, the analog communication setting is over, and the welding operation can be performed in the welding process package, and the process parameters and other information can be directly set in the process library

Installation and Uninstallation#

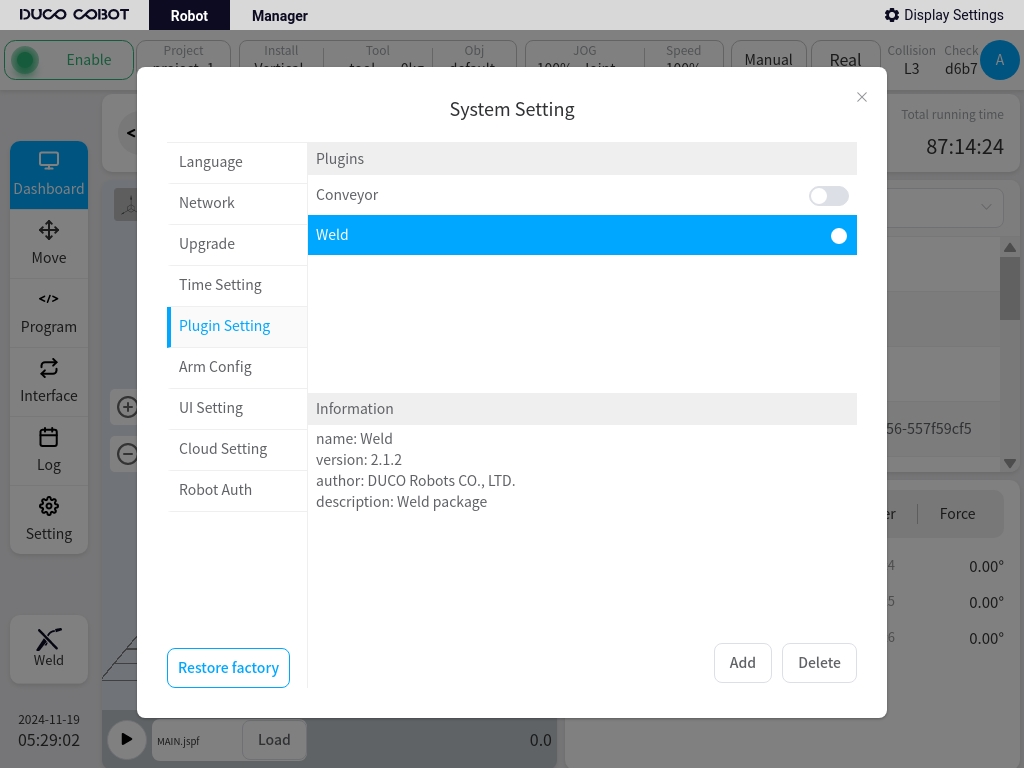

The Weld Process Package V2 plug-in package file is “weld.plugin” and the installation procedure is shown below:

Put the Welding Process Kit V2 plug-in package into a USB flash drive, the USB flash drive requires the format of FAT32.

After the robot system is started, insert a USB flash disk into the USB port on the robot control cabinet.

Login to the robot system using your admin account, click on the user avatar and select System Settings.

Select the plug-in management function, click the Add button.

Select the USB flash drive and from the file list, find and select the “weld.plugin” package.

After the installation of the plug-in package is complete, as shown in the figure below, the top of the page will show a pop-up window plug-in package installation success.

And select the installed plug-ins in the region of the plug-in package, the bottom of the page details will show the name of the current plug-in package, version and other content.

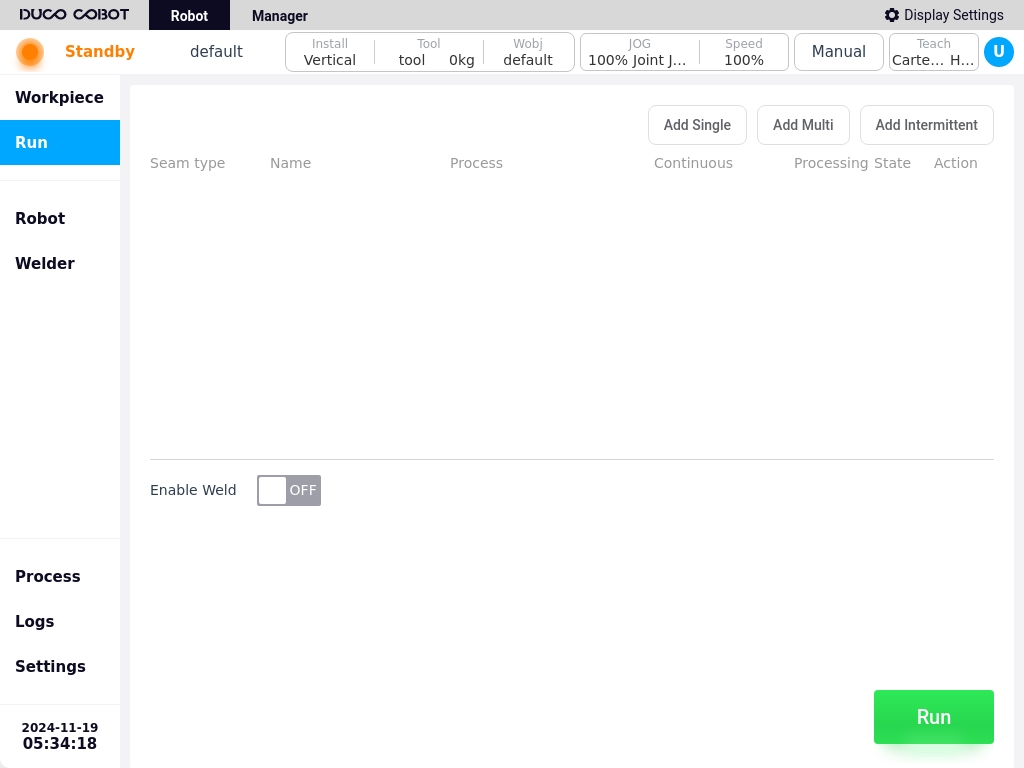

After the installation of Welding Process Pack V2 is completed, the Process Pack Setup Portal will appear on the lower left side of the main page.

Click on this Process Kit Setup Entry button to access the Welding Process Kit V2 login page.

Click on the Login button to access Welding Process Kit V2 as shown below.

The installed Welding Process Package V2 can be temporarily disabled by going to the System Settings - Plug-in Settings page and turning off the enable signal.

Or click the Delete button to remove the plug-in package completely.