Introduction to End Force Control#

functional objectives#

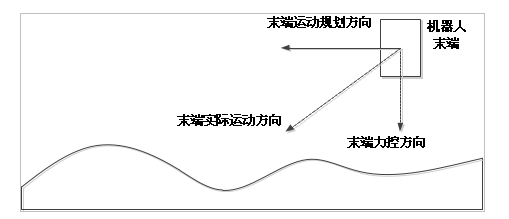

The end force control function enables the robot to sense and interact with the external tool through the force sensor. By choosing to use the end force control function, the end of the robot can make contact with the external environment according to the force in the specified direction set by the user during the movement, especially in the case that the absolute position relationship between the robot and its interactive environment is uncertain. Some typical robot applications for end-force control include precision assembly, grinding and polishing, force performance testing, and high-precision load identification.

Usage restrictions#

When users choose to use the end force control function, they need to pay attention to the following restrictions:

A six-dimensional force sensor is correctly installed and configured at the end of the robot or a six-dimensional force sensor is correctly installed and configured and enabled at the base of the robot.

The total load borne by the end of the robot, including the weight of the end sensor itself, the tool and load installed on the end sensor, the sum of the end sensor of the robot, and the contact force between the tool load and the outside world, shall not exceed the load limit curve specified by the robot.

When the robot end force control function is enabled, the robot collision detection function will fail, even if the collision detection function is enabled by the user.

When the robot end force control function is enabled, the robot will generate movements in the direction of force control beyond the user’s motion instruction, and the user needs to evaluate the safety of such movements according to the actual situation.