End Force traction#

Function description#

When the user chooses to use the end force control traction, the end of robot can be directly dragged and moved in Cartesian space. Compared with the robot’s own traction teaching function, the end force control traction allows the user to control the end of robot to move in a specified direction in a specified coordinate system and limit the non-traction direction to no displacement. By choosing to use the end force control traction, users can obtain higher traction freedom and accuracy.

Function restriction#

When using the end force control traction function, the user should pay attention to the following restrictions:

This function is only available when the force sensor is properly configured and enabled.

Before enabling the function, the user needs to configure the tool load centroid parameters according to the actual tool installed on the force sensor and the load at the end of robot.

If you choose to use the end force sensor, after the function is enabled, the user can only drag the tool and load mounted on the end force sensor to pull, and the drag robot will not cause any movement in other parts.

If the base force sensor is selected, the user can drag the robot to any position after the function is enabled, and the force exerted by the user on the robot will be considered as the force exerted on the tool at the end of robot.

Function operation interface#

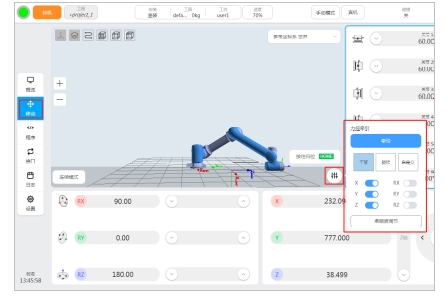

The user can enter the operation interface of the terminal force control traction function in the moving interface, as shown in the figure below:

The operation interface contains the function enable button, traction direction switch, and traction direction compliance adjustment.

Traction coordinate setup#

When using the end force control traction, the user can select different coordinate systems for traction. The selection of the traction coordinate system is the same as that of the robot’s Cartesian space movement function, as shown in the figure below:

After the user enables the end force control traction, the selected traction translation direction X/Y/Z and traction rotation direction RX/RY/RZ will refer to the corresponding direction of the selected coordinate system.

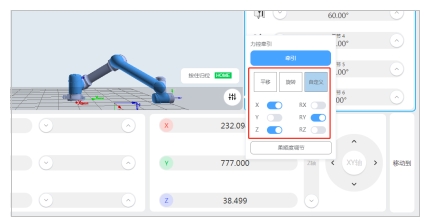

Traction direction Settings#

The user can switch the traction direction in the specified coordinate system according to the actual use requirements, as shown in the following figure:

When the force traction function is enabled, only the activated force traction direction will move according to the generation, and no displacement will occur in the non-activated direction. When the user only needs to pull the translation direction X/Y/Z, the translation mode operation button can be used to automatically open the translation direction and close the rotation direction, as shown in the following figure:

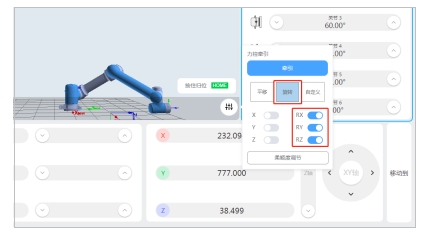

When the user only needs to pull the rotation direction RX/RY/RZ, the rotation mode operation button can be used to automatically open the rotation direction and close the translation direction, as shown in the following figure:

If you want to define the traction direction switch, you can use the custom mode.

Traction compliance Settings#

When the user uses the force control traction function, the traction flexibility can be set according to the demand, as shown in the following figure:

Increasing the traction flexibility in the traction direction will increase the maximum tractable speed in the corresponding traction direction during the use of the end force controlled traction, otherwise it will decrease. The parameters take effect after modifying the end force traction compliance and clicking OK.

On and off traction#

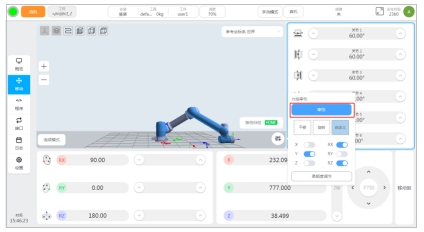

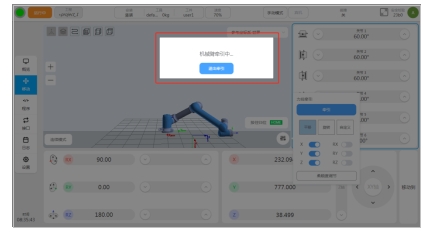

Click the pull button, and the robot will enter the end force control pull mode, as shown in the figure below:

When the robot successfully enters the end force control traction function, the interface will indicate that the robot is in traction, as shown in the figure below:

When the user completes the traction function, click the exit traction button to exit the traction. In order to avoid large external force/moment impact on the end of the robot when it exits traction, the robot should be in a static state as far as possible when it clicks the exit traction button.a