Welding Troubleshooting#

In the welding process, according to the source of the fault, it can usually be divided into three fault modes, welding machine fault, communication fault, robot fault. This chapter describes three troubleshooting methods and how to restart the arc after the fault is rectified.

Welding Machine Failure#

When an error occurs due to the welder, the welder will send the welder error id to the robot. The error id can be queried under the welder signal page. If the signal is configured with the corresponding register, the information can be obtained by reading the register through the external communication interface of the robot. After the failure:

On the side of the welder, the arc closure action will be performed automatically.

On the robot side, the program will be suspended after receiving an error message from the welder.

Communication Failure#

During use, if the communication is affected, the CAN communication between the welding machine is interrupted:

At the welder side, communication interruption will be detected within 1 second, communication error will be reported, and automatic arc closure action will be performed.

On the robot side, a communication interruption is detected within 3 seconds, a communication error is reported, and the program is suspended.

Robot Malfunctions#

When an error occurs due to the robot, the robot will send a robot fault signal to the welder.

On the side of the welder, after receiving the error signal from the robot, the welder will automatically perform the arc closure action.

On the robot side, when the robot reports an error, the program will be paused.

Re-arc#

After a fault occurs, the robot program pauses and automatically records the current pause point information. At this time, the robot is allowed to move away from the current point in a manual jog, which is convenient for the user to troubleshoot.

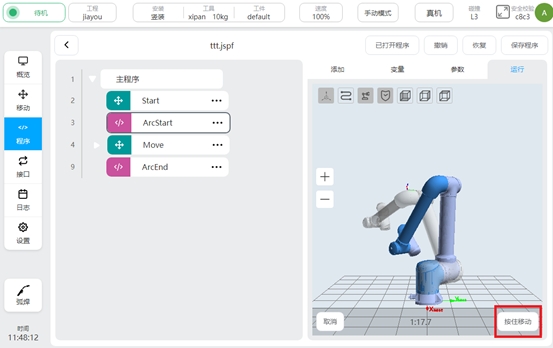

When the fault is rectified, clicking the program to run again will ask the user to return to the pause point first. The way to return to the pause point is movej. As shown in the picture below:

Press and hold the “Press and move” button, the robot moves in the way of movej, and the movement stops when you release it. To prevent the movej from bumping into other objects in its path, it is recommended that the user return to the pause point in advance in a manual jog.

After returning to the pause point, switch the robot to automatic mode, click continue to run the program, the robot will send the arc starting command to the welder, and continue to execute the subsequent program after the arc is successfully started.