Instruction control of the mechanical arm and related interface call instructions#

Method 2: Controlling the Robotic Arm via Terminal Commands#

We can use RobotControl, RobotIoControl, and RobotMove commands to control the robotic arm’s power enablement, input/output, and movement respectively.

Important Notes:

All commands require a space after the colon ‘:’

Command parameters can be found in the relevant srv files under src/duco_msg/srv

Before using commands, complete the configuration process and package compilation described in previous chapters.

After preparing your environment, navigate to the src resource package directory, open a terminal, and execute commands.

Below are detailed explanations of available commands:

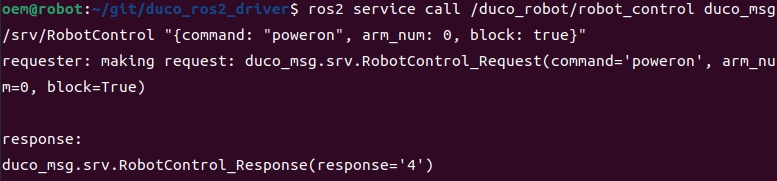

RobotControl#

Controls power and enablement state of the robotic system.

Input Parameters:

string command: Instruction

int8 arm_num: Arm number (set to 0)

bool block: Blocking instruction (false = non-blocking command that returns immediately)

string response: Return message (string)

Available Commands:

poweron (Power on)

enable (Enable movement)

disable (Disable movement)

poweroff (Power off)

Command Template:

1ros2 service call /duco_robot/robot_control duco_msg/srv/RobotControl "{command: '', arm_num: , block: }"

Command Example:

1ros2 service call /duco_robot/robot_control duco_msg/srv/RobotControl "{command: 'poweron', arm_num: 0, block: true}"

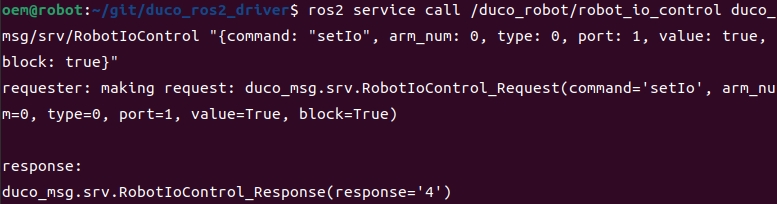

RobotIoControl#

Configures and retrieves general purpose I/O.

Input Parameters:

string command: Instruction

int8 arm_num: Arm number (set to 0)

int8 type: I/O type (0 = general I/O, 1 = tool I/O)

int8 port: I/O port (GEN I/O range 1-16, TOOL I/O range 0-1)

bool value: SetIO value

bool block: Blocking instruction (false = non-blocking)

string response: Return message (string)

Available Commands:

setIo (Configure output)

getIo (Retrieve input)

Command Template:

1ros2 service call /duco_robot/robot_io_control duco_msg/srv/RobotIoControl "{command: '', arm_num: , type: , port: , value: , block: }"

Command Example:

1ros2 service call /duco_robot/robot_io_control duco_msg/srv/RobotIoControl "{command: 'setIo', arm_num: 0, type: 0, port: 1, value: true, block: true}"

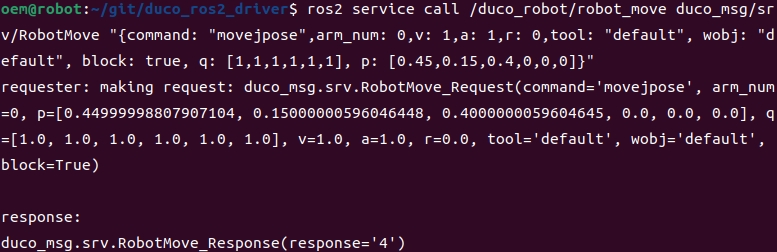

RobotMove#

Controls robotic arm movement.

Input Parameters:

string command: Instruction

int8 arm_num: Arm number (set to 0)

float32[] p: Cartesian target position (x,y,z,rx,ry,rz)

float32[] q: Target joint angles in radians

float32 v: Max end-effector linear velocity (range: 0.01-5 m/s)

float32 a: Max end-effector linear acceleration (range: 0.01-∞ m/s²)

float32 r: Trajectory blend radius (meters, 0 = no blending)

string tool: Tool name (“default”)

string wobj: Workobject coordinate system (“default”)

bool block: Blocking instruction

string response: Return message (string)

Available Commands:

movej: Joint space move to target joint angles

movej2: Synchronized phase move to target joint angles

movejpose: Joint space move to target end-effector position

movejpose2: Synchronized phase move to target end-effector position

movel: Linear Cartesian move to target pose

movetcp: Linear incremental move in tool coordinate system

Command Template:

1ros2 service call /duco_robot/robot_move duco_msg/srv/RobotMove "{command: '', arm_num: , v: , a: , r: , tool: '', wobj: '', block: , q: [,,,,,], p: [,,,,,]}"

Command Example:

1ros2 service call /duco_robot/robot_move duco_msg/srv/RobotMove "{command: 'movejpose', arm_num: 0, v: 1, a: 1, r: 0, tool: 'default', wobj: 'default', block: true, q: [1,1,1,1,1,1], p: [0.49,0.14,0.44,-1.14,0,-1.57]}"

API Documentation#

RobotControl#

1/**

2 * @brief: Robot power on;

3 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

4 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

5 */

6int32_t power_on(bool block)

7// Example:

8power_on(true)

9

10/**

11 * @brief: Robot power off;

12 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

13 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

14 */

15int32_t power_off(bool block)

16// Example:

17power_off(true)

18

19/**

20 * @brief: Robot enable;

21 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

22 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

23 */

24int32_t enable(bool block) ;

25// Example:

26enable(true)

27

28/**

29 * @brief: Robot disable;

30 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

31 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

32 */

33int32_t disable(bool block) ;

34// Example:

35disable(true)

RobotIoControl#

1 /**

2 * @brief: Read the high/low level of the robot end-effector's digital input port. Returns true for high level, false for low level;

3 * @param num: End-effector digital input port number, range 1-2;

4 * @return: true for high level, false for low level;

5 */

6bool get_tool_digital_in(int16_t num) ;

7// Example:

8get_tool_digital_in(1)

9

10/**

11 * @brief: Read the high/low level of the control cabinet's user digital input port. Returns true for high level, false for low level;

12 * @param num: Control cabinet input port number, range 1-16;

13 * @return: true for high level, false for low level;

14 */

15bool get_standard_digital_in(int16_t num) ;

16// Example:

17get_standard_digital_in(1)

18

19 /**

20 * @brief: Set end-effector digital output;

21 * @param num: End-effector digital output port number, range 1-2;

22 * @param value: true for high level, false for low level;

23 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

24 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

25 */

26int32_t set_tool_digital_out(int16_t num, bool value, bool block) ;

27// Example:

28set_tool_digital_out(1, true, true)

29

30/**

31 * @brief: Control the high/low level of the control cabinet's digital output port;

32 * @param num: Control cabinet output port number, range 1-16;

33 * @param value: true for high level, false for low level;

34 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

35 * @return: Blocking execution returns the task end status, non-blocking execution returns the task ID;

36 */

37int32_t set_standard_digital_out(int16_t num, bool value, bool block) ;

38// Example:

39set_standard_digital_out(1, true, true)

RobotMove#

1 /**

2 * @brief: Move robot from current state to target joint angles via joint motion;

3 * @param: joints_list Target joint angles for joints 1-6, unit: rad;

4 * @param v: Joint angular velocity, unit: percentage of system set speed %, range (0,100];

5 * @param a: Joint angular acceleration, unit: percentage of system set acceleration %, range (0,100];

6 * @param: r: Blend radius, unit: percentage of maximum system blend radius %, default 0 (no blending), range [0,50);

7 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

8 * @param op: Optional parameter;

9 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

10 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

11 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

12 */

13int32_t movej(const std::vector<double> & joints_list, double v, double a, double r, bool block, const OP &op = _op, bool def_acc = false) ;

14// Example:

15movej([1,1,1,1,1,1], 1, 1, 0, true)

16

17/**

18 * @brief: Move robot from current state to target joint angles via joint motion;

19 * @param: joints_list Target joint angles for joints 1-6, unit: rad;

20 * @param v: Joint angular velocity, range [0.01*PI/180, 1.25*PI], unit: rad/s;

21 * @param a: Joint angular acceleration, range [0.01*PI/180, 12.5*PI], unit: rad/s²;

22 * @param r: Blend radius, unit: m, default 0 (no blending). Value >0 indicates blending with next motion;

23 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

24 * @param op: Optional parameter;

25 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

26 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

27 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

28 */

29int32_t movej2(const std::vector<double> & joints_list, double v, double a, double r, bool block, const OP &op = _op, bool def_acc = false) ;

30// Example:

31movej2([1,1,1,1,1,1], 1, 1, 0, true)

32

33 /**

34 * @brief: Move robot via joint motion to target end-effector pose;

35 * @param p: Target end-effector pose, position unit: m, orientation as Rx,Ry,Rz in rad;

36 * @param v: Joint angular velocity, unit: percentage of system set speed %, range (0,100];

37 * @param a: Joint acceleration, unit: percentage of system set acceleration %, range (0,100];

38 * @param r: Blend radius, unit: percentage of maximum system blend radius %, default 0 (no blending), range [0,50);

39 * @param q_near: Nearby joint angles for inverse kinematics solution. Uses current position if empty;

40 * @param tool: Tool coordinate system to use. Defaults to current tool if empty;

41 * @param wobj: Workpiece coordinate system to use. Defaults to current wobj if empty;

42 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

43 * @param op: Optional parameter;

44 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

45 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

46 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

47 */

48int32_t movej_pose(const std::vector<double> & p, double v, double a, double r, const std::vector<double> & q_near, const std::string& tool, const std::string& wobj, bool block, const OP &op = _op, bool def_acc = false) ;

49// Example:

50movej_pose([0.49,0.14,0.44,-1.14,0,-1.57], 1, 1, 0, [1,1,1,1,1,1], "default", "default", true)

51

52/**

53 * @brief: Move robot via joint motion to target end-effector pose;

54 * @param p: Target end-effector pose, position unit: m, orientation as Rx,Ry,Rz in rad;

55 * @param v: Joint angular velocity, range [0.01*PI/180, 1.25*PI], unit: rad/s;

56 * @param a: Joint acceleration, range [0.01*PI/180, 12.5*PI], unit: rad/s²;

57 * @param r: Blend radius, unit: m, default 0 (no blending). Value >0 indicates blending with next motion;

58 * @param q_near: Nearby joint angles for inverse kinematics solution. Uses current position if empty;

59 * @param tool: Tool coordinate system to use. Defaults to current tool if empty;

60 * @param wobj: Workpiece coordinate system to use. Defaults to current wobj if empty;

61 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

62 * @param op: Optional parameter;

63 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

64 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

65 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

66 */

67int32_t movej_pose2(const std::vector<double> & p, double v, double a, double r, const std::vector<double> & q_near, const std::string& tool, const std::string& wobj, bool block, const OP &op = _op, bool def_acc = false) ;

68// Example:

69movej_pose2([0.49,0.14,0.44,-1.14,0,-1.57], 1, 1, 0, [1,1,1,1,1,1], "default", "default", true)

70

71/**

72 * @brief: Move robot end-effector along a straight path to target pose;

73 * @param p: Target end-effector pose, position unit: m, orientation as Rx,Ry,Rz in rad;

74 * @param v: End-effector velocity, range [0.00001, 5], unit: m/s;

75 * @param a: End-effector acceleration, range [0.00001, ∞], unit: m/s²;

76 * @param r: Blend radius, unit: m, default 0 (no blending). Value >0 indicates blending with next motion;

77 * @param q_near: Nearby joint angles for inverse kinematics solution. Uses current position if empty;

78 * @param tool: Tool coordinate system to use. Defaults to current tool if empty;

79 * @param wobj: Workpiece coordinate system to use. Defaults to current wobj if empty;

80 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

81 * @param op: Optional parameter;

82 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

83 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

84 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

85 */

86int32_t movel(const std::vector<double> & p, double v, double a, double r, const std::vector<double> & q_near, const std::string& tool = "default", const std::string& wobj = "default", bool block = true, const OP &op = _op, bool def_acc = false) ;

87// Example:

88movel([0.49,0.14,0.44,-1.14,0,-1.57], 1, 1, 0, [1,1,1,1,1,1])

89

90/**

91 * @brief: Move robot along a straight path in tool coordinate system by specified offset;

92 * @param pose_offset: Pose offset in tool coordinate system;

93 * @param v: Linear velocity, range [0.00001, 5], unit: m/s (if x,y,z all 0, converted proportionally to angular velocity);

94 * @param a: Acceleration, range [0.00001, ∞], unit: m/s²;

95 * @param r: Blend radius, unit: m, default 0 (no blending). Value >0 indicates blending with next motion;

96 * @param tool: Tool coordinate system to use. Defaults to current tool if empty;

97 * @param block: Whether to block. If false, it's a non-blocking command and will return immediately;

98 * @param op: Optional parameter;

99 * @param def_acc: Whether to use system default acceleration. false uses custom acceleration, true uses system auto-planned acceleration. Optional, default false;

100 * @return: Blocking execution: returns task end status (Finished if no blending, Interrupt if blended);

101 * Non-blocking execution: returns task ID for querying execution status via get_noneblock_taskstate(id);

102 */

103int32_t tcp_move(const std::vector<double> & pose_offset, double v, double a, double r, const std::string& tool, bool block, const OP &op = _op, bool def_acc = false) ;

104// Example:

105movetcp([0.49,0.14,0.44,-1.14,0,-1.57], 1, 1, 0, "default", "default")