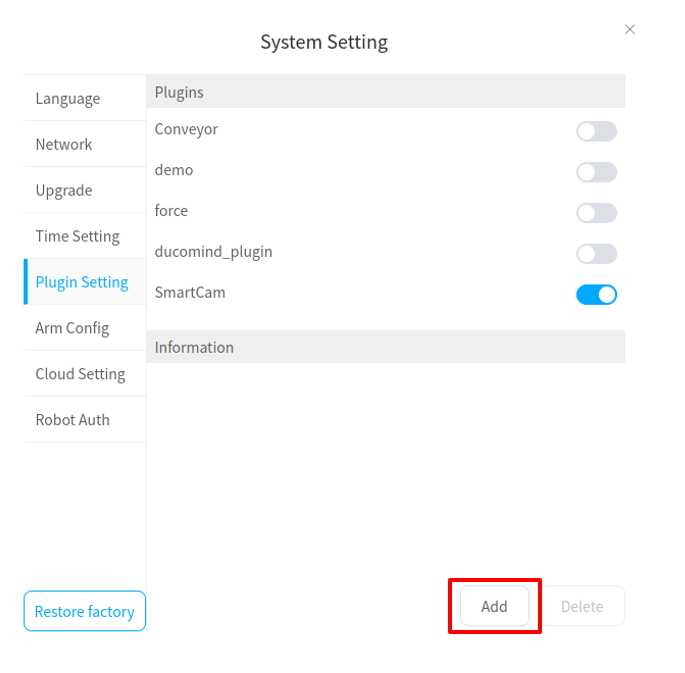

Plugin Configuration#

Check whether the robot plugin is installed. If it is successfully installed, open SmartCam in the plugin management interface in the system test.

When opening the calibration interface of the SCMVS software to test the calibration, it is necessary to change the SmartCam’s mode to configuration mode. After configuring the SCMVS software calibration plug-in, it is then necessary to change the SmartCam’s mode to run mode.

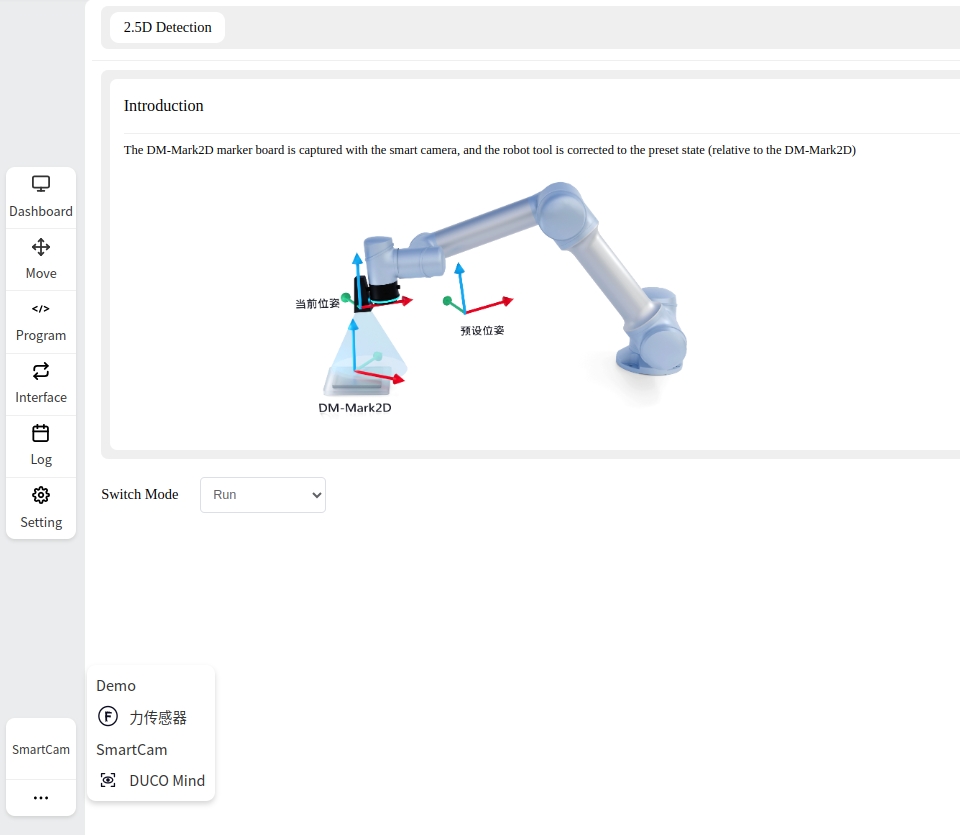

2.5DDetectionSmart#

The 2.5DDetectionSmart block can be found in the command interface. It is necessary to configure the project, enter the name of the trigger project, and the communication string. The name of the project is the project name set in the SCMVS configuration. The communication string is configured by default to start. The parameter details are as follows:

Maximum accumulated correction displacement: During the correction process, the accumulated distance moved by the robot is summed up. If the accumulated distance moved by the robot is greater than the maximum accumulated correction displacement, the correction process will be terminated and the correction will be completed. It is recommended that the value be set to 80.

Maximum accumulated correction angle: During the correction process, the accumulated angle of the robot’s movement is summed up. If the accumulated angle of the robot’s movement is greater than the maximum accumulated correction angle, the correction process will be terminated and the correction will end. It is recommended to set it to 20.

Maximum servo correction times: During the correction process, the cumulative number of times the robot moves is accumulated. If the cumulative number of times the robot moves is greater than the maximum servo correction times, the correction process will be terminated and the correction will end. It is recommended to set it to 5.

Termination condition - displacement error: During the correction process, if the displacement deviation between the identified marker plate pose and the pose recorded in the reference is less than the termination condition, and the termination condition for angle error is also met, then the correction process will terminate and the correction will end. It is recommended to set it to 0.3.

Termination condition - angle error: During the correction process, if the angle deviation between the identified pose of the marker plate and the pose recorded by the reference is less than the termination condition, and if the termination condition for displacement error is also met, then the correction process is terminated and the correction is complete. It is recommended to set it to 0.28.

Correction test: The robot can be offset to verify whether the set parameters are reasonable and meet the cycle.

IO Variable:Recognition success, correction success. Identify, output the pose of the marker code in the robot base coordinate system at this time.

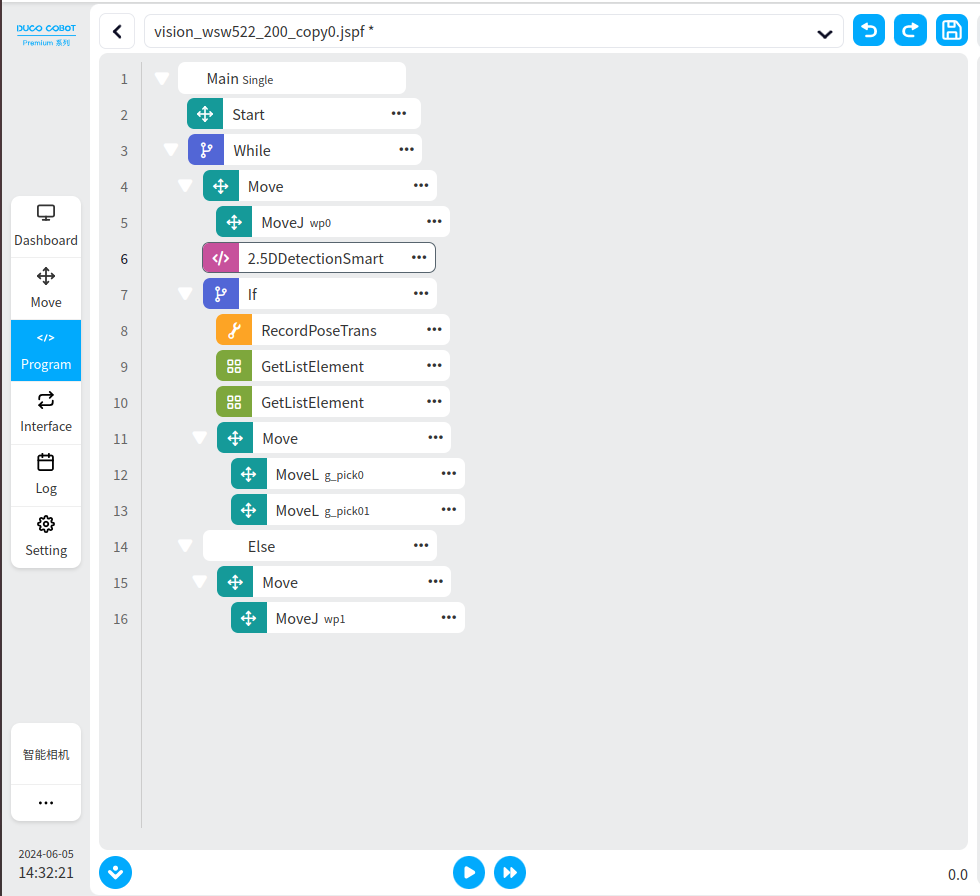

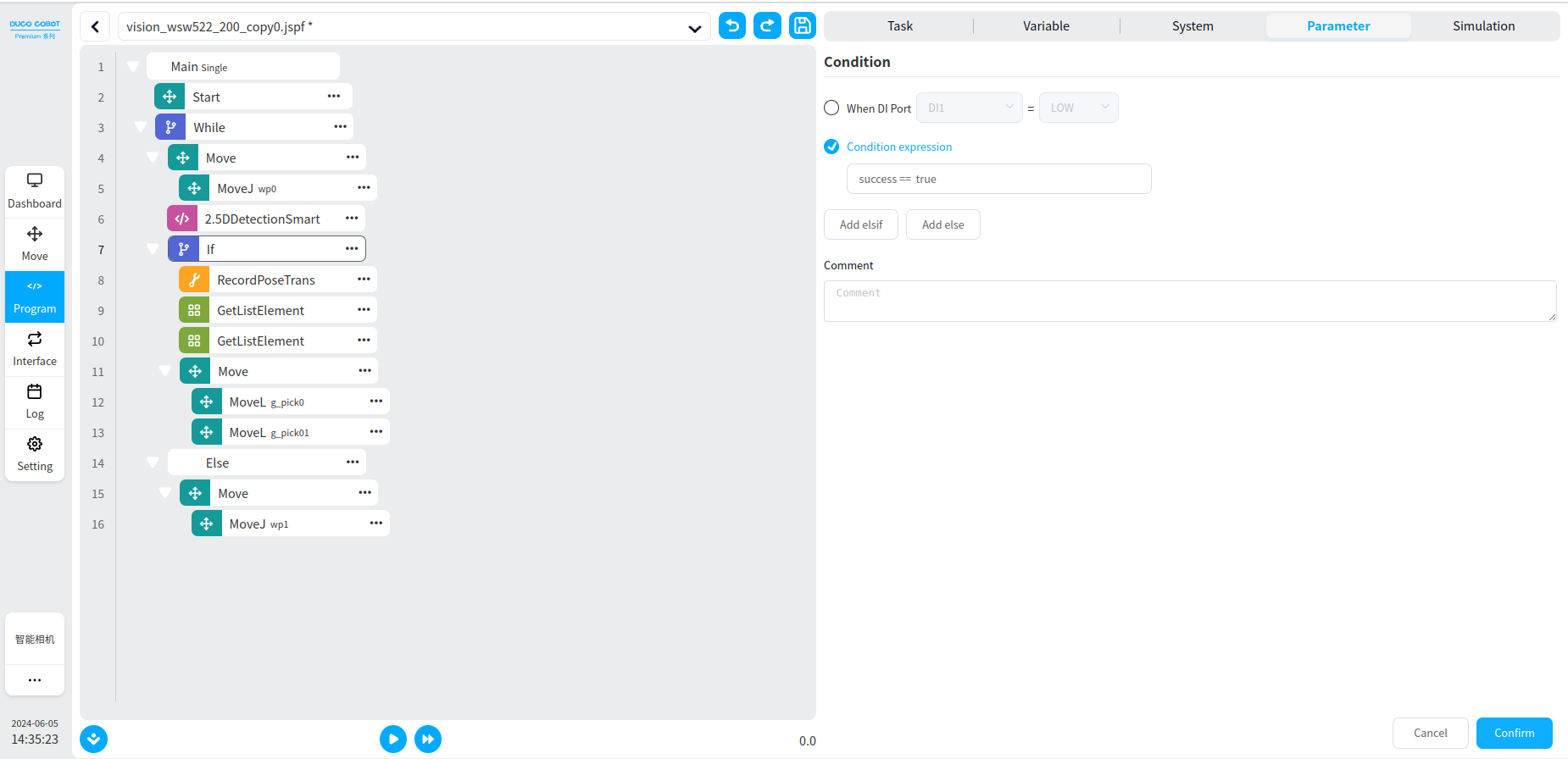

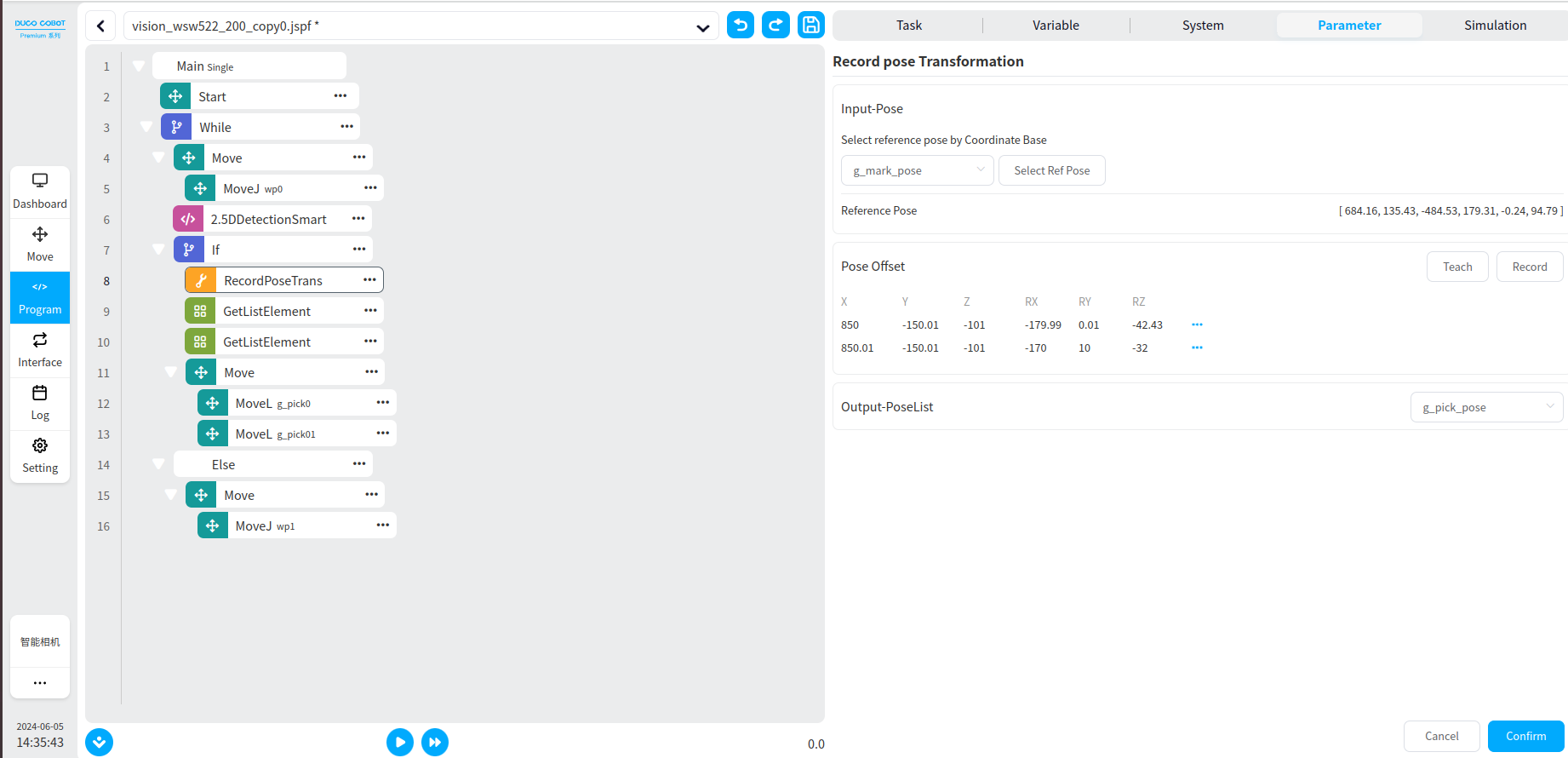

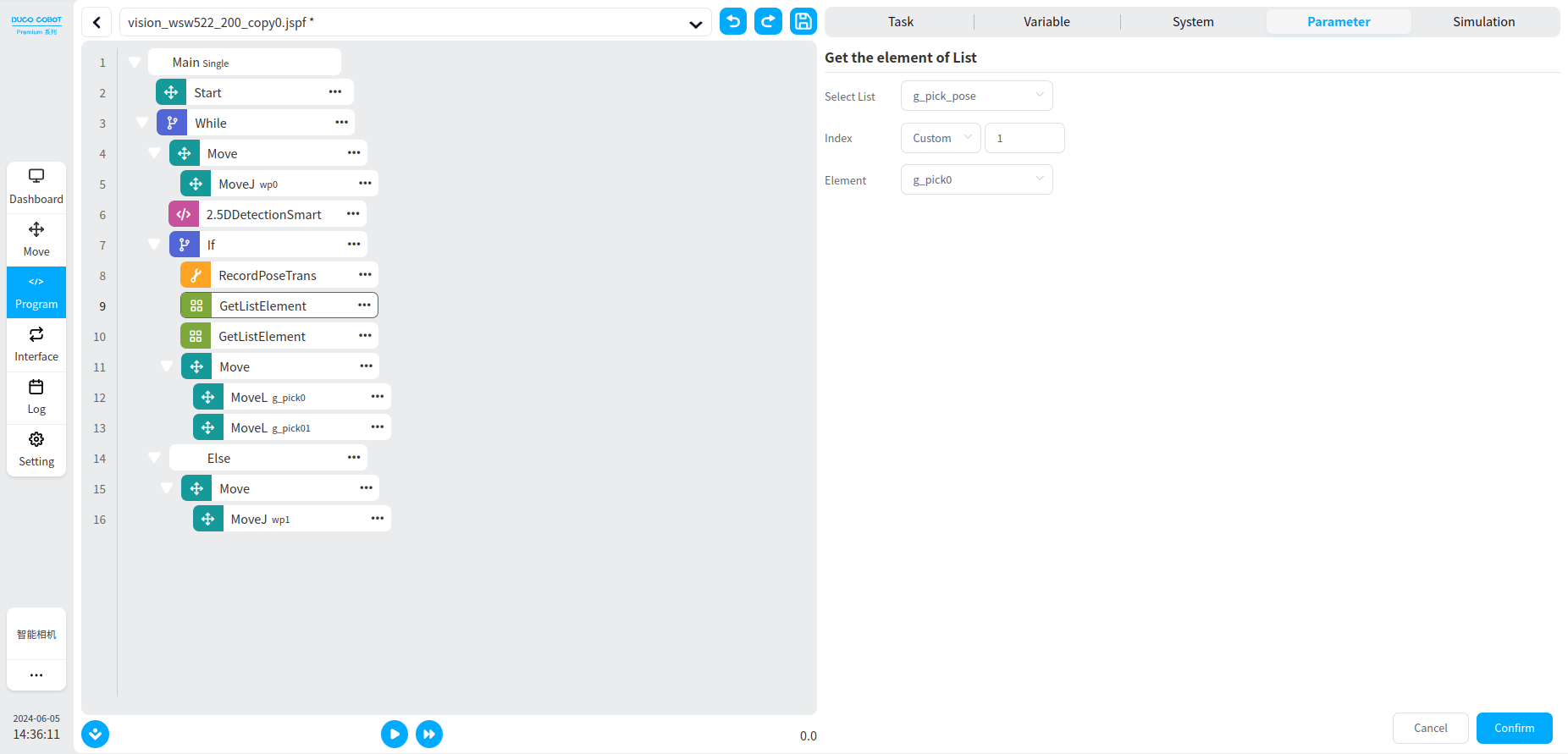

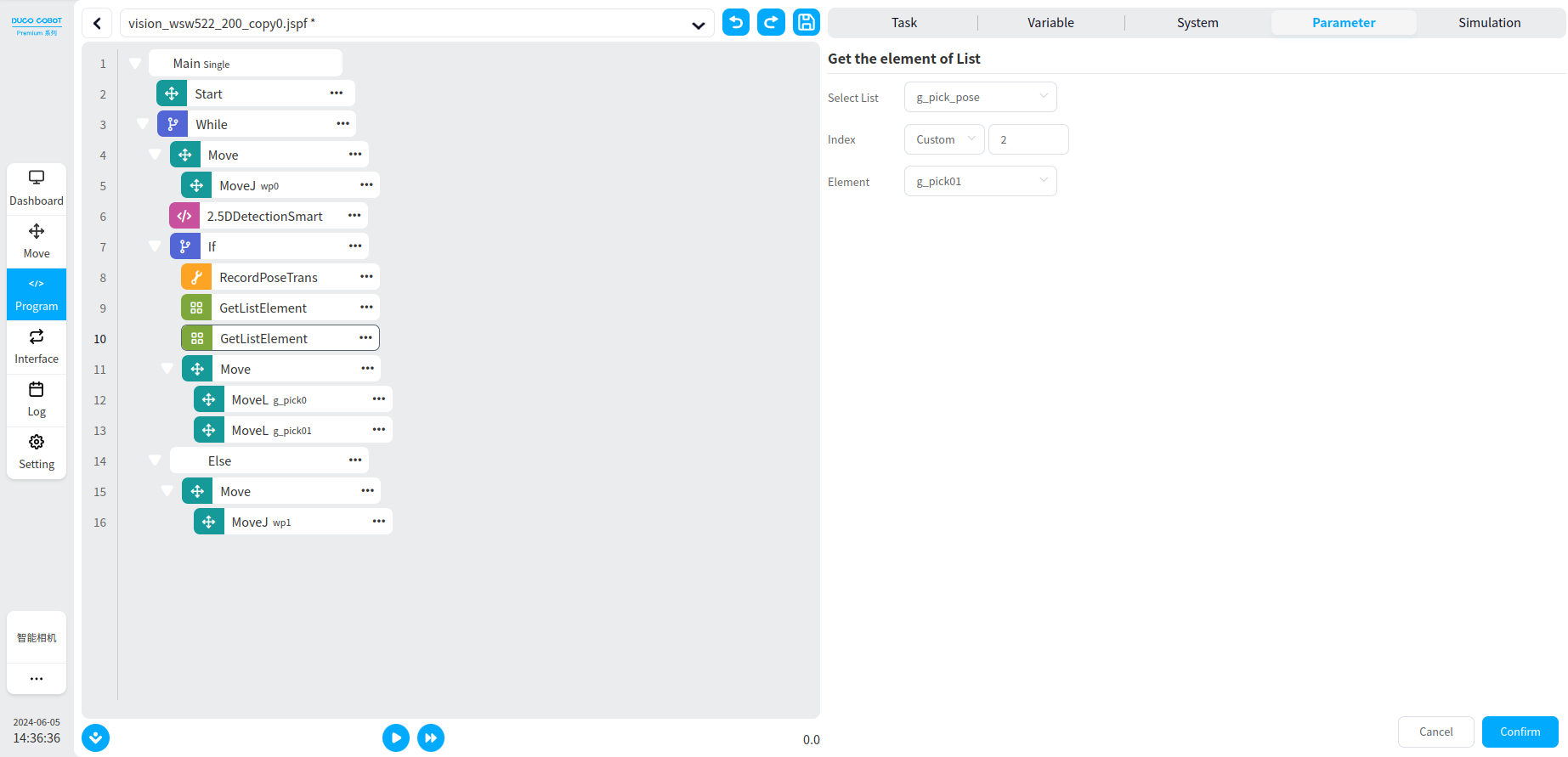

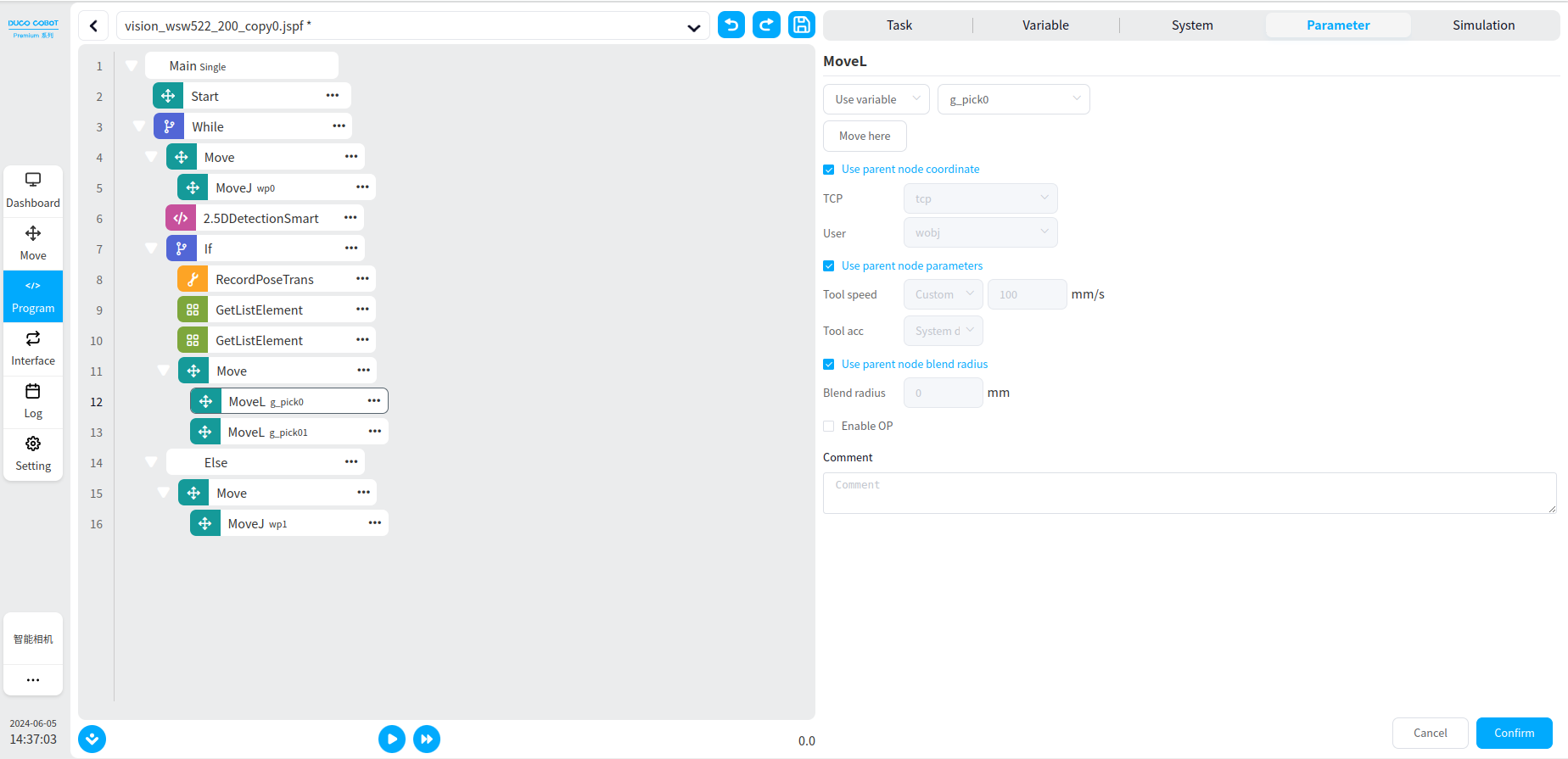

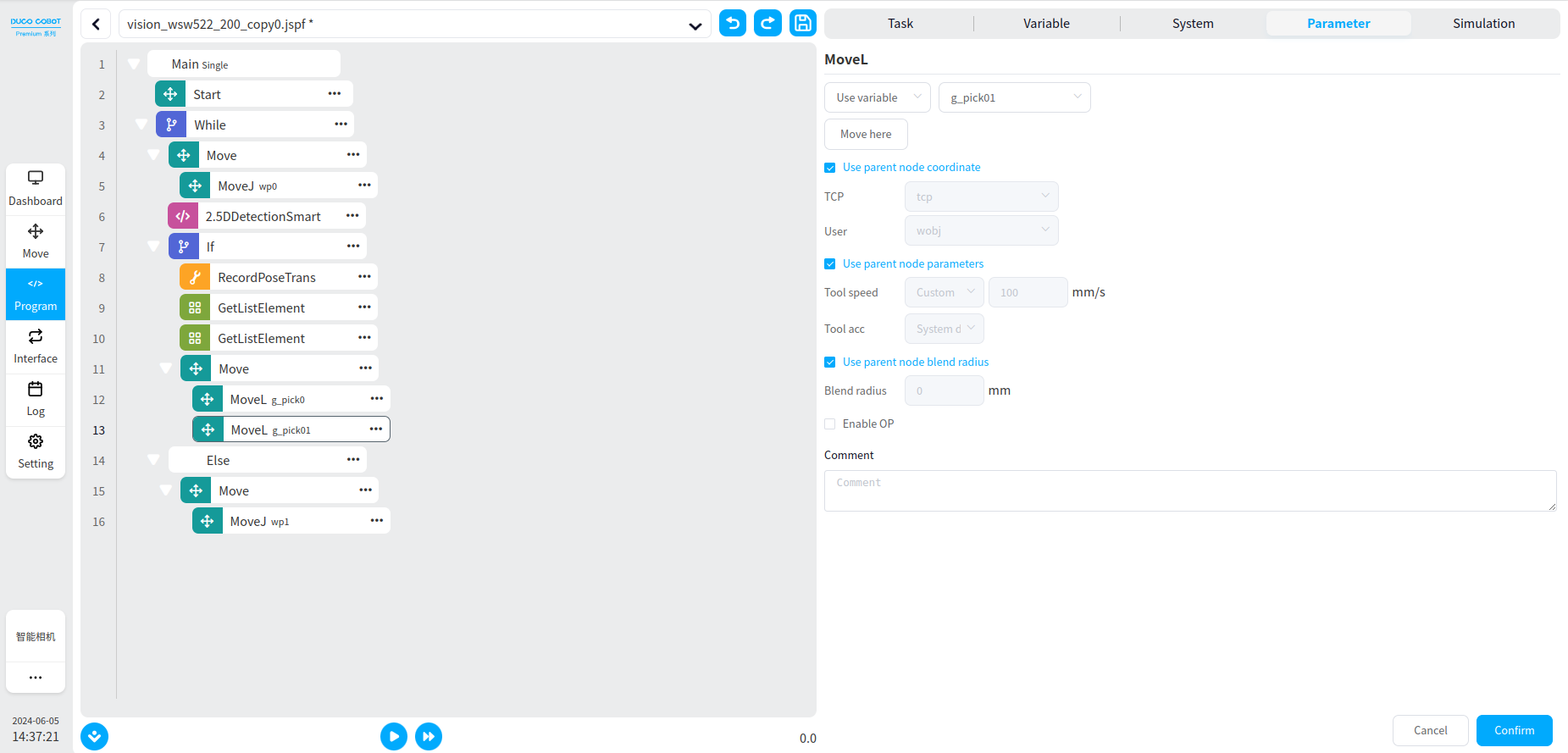

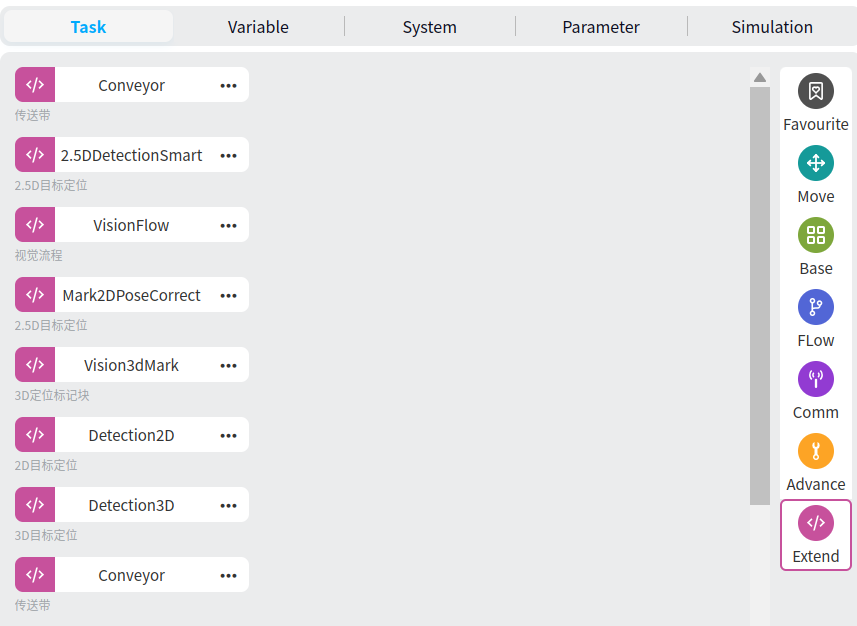

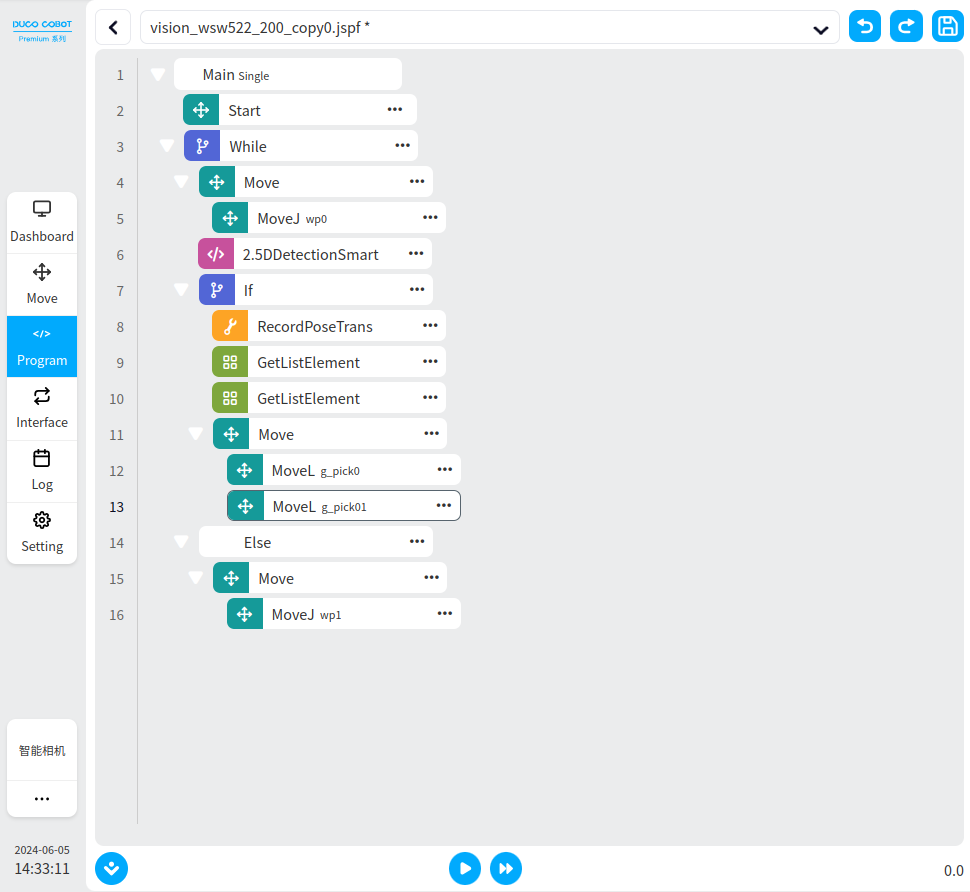

A simple flow chart of the use of the program block is shown below.

Functions of Program