Maintenance and repair#

Maintenance and repair work must strictly follow all safety instructions in this manual.

Maintenance must be done by an authorized system integrator or Siamatsu staff.

Parts returned to Siamatsu should be operated according to the service manual.

Safety instruction#

After maintenance, checks must be made to ensure the level of safety required by the service. Compliance with valid national or local safety laws and regulations is mandatory. At the same time, check whether all safety functions are normal.

The purpose of maintenance is to ensure the normal operation of the system, or to help the system return to normal operation in the event of a failure. Maintenance includes fault diagnosis and actual maintenance.

The following safety procedures and warnings must be followed when operating a control cabinet or robot:

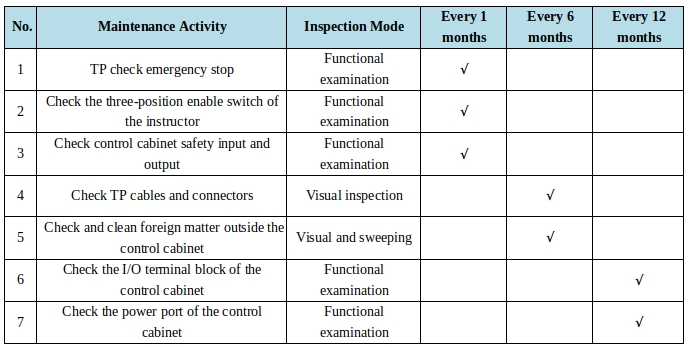

Maintenance items and cycles#

In order for the robot system to maintain a high performance for a long time, it is necessary to carry out maintenance checks. The personnel responsible for maintenance shall prepare maintenance plan and carry out maintenance according to the plan. The maintenance items refer to the following table. If you have any questions, please contact the service department of the company.

Component replacement#

When replacing parts of the control cabinet, observe the following precautions to safety perform operations.