Maintenance#

Maintenance and repair work must strictly follow all safety instructions in this manual.

Maintenance, calibration and repair work must be carried out according to the latest service manual.

Safety instruction#

After maintenance, the safety level of the system must be checked again. Verification must comply with valid standards and safety laws and regulations. All safety features should also be tested to ensure that they are working properly.

The purpose of maintenance is to ensure the normal operation of the system, or to help the system return to normal operation in the event of a failure. Maintenance includes fault diagnosis and actual maintenance.

Safety measures to be taken during maintenance operations include:

The first condition before maintenance:

The robot must be kept switched off and have protective measures to prevent accidental restart.

Remove the main input cable to ensure complete power failure, disconnecting other energy sources. Take precautions to avoid system power reconnection during maintenance.

Before restarting the system, check whether the ground connection is properly connected.

Wait 5 minutes until the intermediate circuit is fully discharged. Avoid splitting the power supply system in the control cabinet. The high voltage can be retained in the power supply system for several hours after the control cabinet is closed.

Follow ESD guidelines when disassembling robot arms or control cabinets.

The pneumatic system is a part of the system independent of the robot and fixture. After the main power supply of the robot is turned off, the air pressure remains. The robot’s power supply must be cut off and the pressure released before installing or servicing the fixture.

Note:

Do not change any information (such as force limits) in the software safety configuration. The safety configuration is described in the manual. If safety parameters change, the entire robot system should be considered new, which means that all safety audit processes, such as risk assessment, must be updated.

Replace the failed part with a new part with the same part number or an approved equivalent.

Reactivate all disabled safety measures immediately after maintenance is completed.

Document all maintenance operations in writing and keep them in technical documentation related to the entire robot system.

maintenance#

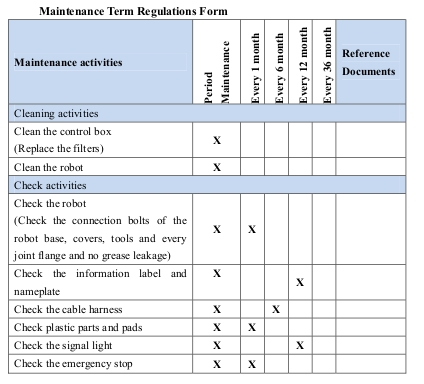

After the completion of equipment commissioning, the maintenance work shall be carried out according to the specified maintenance period.

Maintenance Period Specification Form

Regular:

The actual interval depends on the robot’s operating cycle, working environment and movement mode. In general, the shorter the operation cycle, the more serious the pollution of the working environment, the more demanding the movement mode, and the shorter the interval of regular maintenance. When performing a job in the maintenance list, a visual inspection must be carried out according to the following points:

Check that safety devices, plug connections and printed circuit boards are safety installed;

Check whether the label and nameplate are clear and complete;

Check the cable for damage;

Check the connection of ground potential balancing wires;

Check all equipment components for wear or damage.

Robot cleaning#

Dust/dirt/oil observed on the robot can be wiped off using a clean cloth and water or 10% ethanol. In some extreme cases, a small amount of oil may spill from the joint, which does not affect the performance or life of the joint.

Control cabinet cleaning#

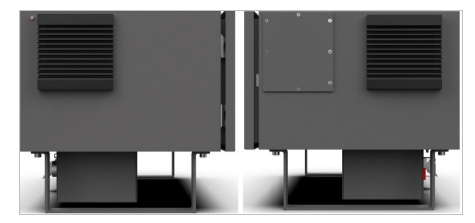

The control cabinet package contains two fan shields on both sides, and is equipped with IP44 filter screen, which is mainly used for internal heat dissipation of the control cabinet.

Notice Adjust the direction of the fan dust cover for different control cabinets. Otherwise, the IP protection level will be affected.

Figure 6-81 Diagram of installing fan dust cover on the side of the control cabinet

Fan filter cleaning procedure:

As shown in the following figure, there are two gaps in the red box. Insert a small flat-head screwdriver into the gap and pry outward. Remove the dust cover when it becomes loose.

Take out the filter screen, according to the actual situation of the filter screen to confirm the use of low-pressure gas cleaning or direct replacement of the filter screen, cleaning the filter screen needs to be repeatedly cleaned on the front and back sides to ensure that the filter screen is thoroughly cleaned.

Figure 6-82 Filter screen cleaning of control cabinet

repair#

Only trained users are allowed to perform repair work on the robot controller. Repair work within equipment components is allowed only by trained personnel. Maintenance must be performed according to the latest maintenance manual.