Transportation and Storage#

This chapter contains information on transport and storage robots. This paper mainly introduces the basic matters that should be paid attention to in each component of the transportation storage robot system.

transport#

preconditions#

Robot:

Keep the original packaging during transportation and store the packaging materials in a dry place. The robot may then need to be packaged and moved. Lift the robot tube while moving the robot from the robot’s packaging material to the installation position. Hold the robot until all bolts on the base of the robot are fastened. The robot should remain in the packing pose throughout the transportation process until it is secured (see Chapter 5).

Control system:

The control cabinet should be kept upright during transportation and placement, and vibration and collision should be avoided during transportation to avoid damage to the control system.

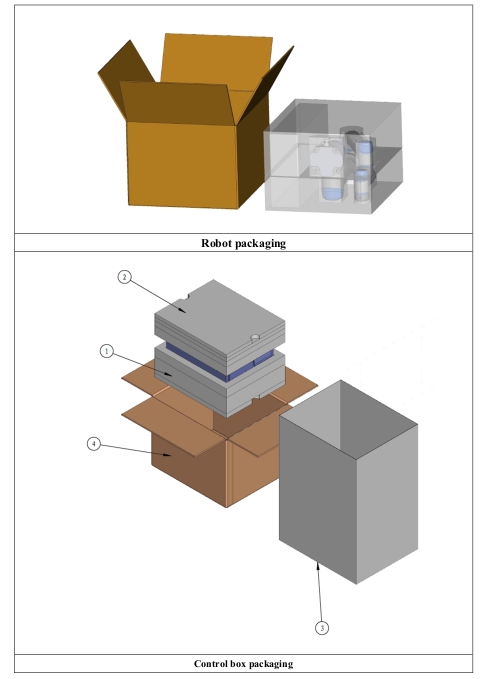

Robot packaging#

Packing steps are as follows:

Loosen and unplug any external tools and peripherals.

Move the robot to the packing posture and turn off the robot power.

Loosen and disconnect the robot from the control cabinet.

Pull out the ground safety lead and remove the screws.

Clean and dry the robot.

Place the robot in the packing box.

Pack the robot and control cabinet into the specified packing box. Ensure that the robot and control cabinet are oriented correctly.

deposit#

preconditions#

Long-term storage robots must pay attention to the following points:

Storage place should be dry and dust-free

Avoid temperature fluctuations

Avoid condensation

Avoid direct sunlight

Avoid drafts

Select a reasonable storage temperature range

Choose a storage location that will not damage the packaging

Only store the robot control system in a closed space

Operation procedure#

The steps to store the robot are as follows:

Loosen and unplug the peripheral port.

Move the robot to the packing posture and turn off the robot power supply.

Loosen and disconnect the robot from the control cabinet.

Pull out the ground safety lead and remove the screws.

Clean and dry the robot.

Put the robot in the packing box.

Prepare the robot for storage.

The robot is operated after long-term storage#

The robot uses harmonic gear technology, the joints are partially sealed and self-lubricating (no need to change or add grease during its service life). During normal operation, lubricating oil is naturally distributed around gears and bearings to maintain normal lubrication of the mechanical system. When the robot is stored or stopped for more than 1 month, or the joint is in a very small range of motion for a long time, it is recommended to take the following measures periodically, which will help the service life of the robot.

Before switching on the power supply, please put the robot at room temperature (such as stored in a cold environment);

Switch on the power supply of the robot and keep it in a static state for 30min, which will enable the robot to reach its internal working temperature and soften the grease;

In manual mode, slowly move all joints one by one, taking care not to load any payload and tools;

Create a program to move all joints slowly and continuously for at least 20 minutes (default acceleration is recommended, the speed is set around 10°/s, and the joints are rotated as far as possible).