Welding machine control#

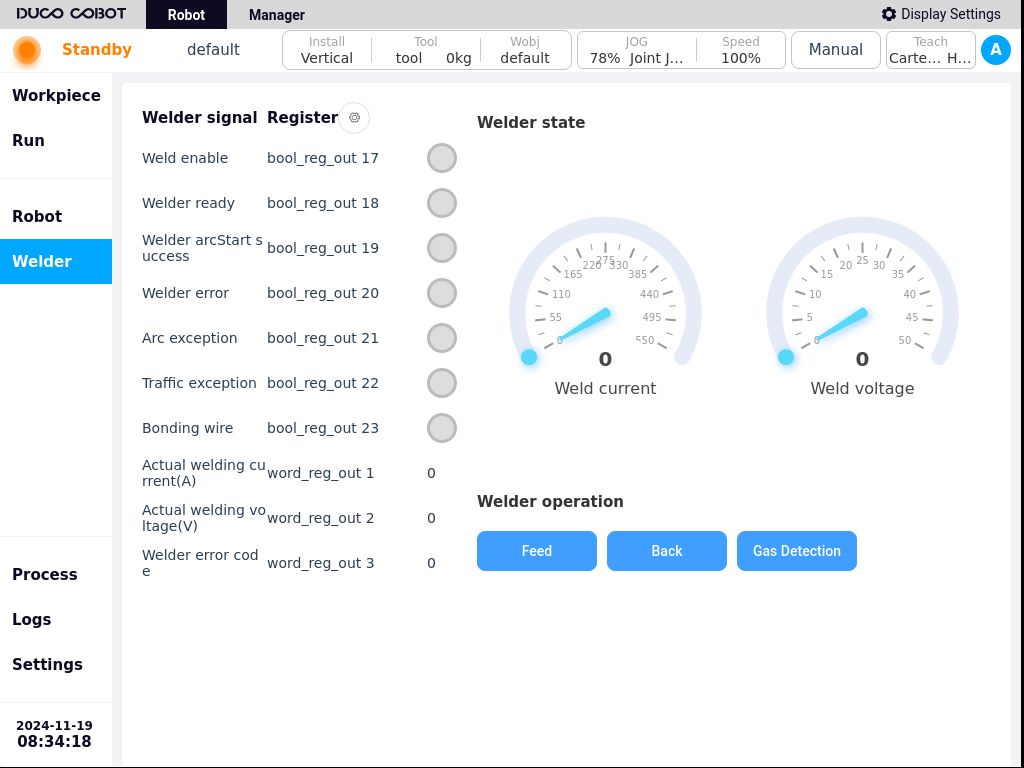

Click “Welder Control” in the navigation bar to enter the welder control page, as shown below.

The welder control page is mainly used to display welder signals, welder status and welder operations. Among them, the welder signal can be configured to the register.

This allows the robot controller to access the welder information via profinet, modbus, TCP/IP, etc.

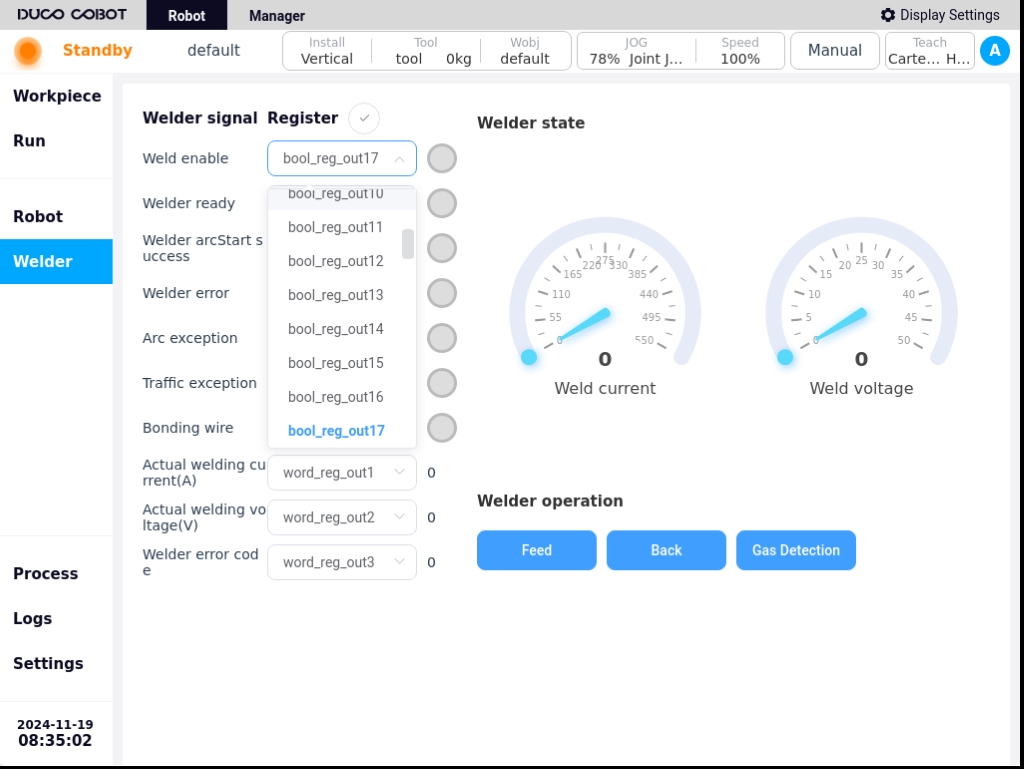

Click on the  icon next to the registers to configure the registers. A list of configurable registers is displayed to the right of the signals, as shown in the following figure.

icon next to the registers to configure the registers. A list of configurable registers is displayed to the right of the signals, as shown in the following figure.

After completing the register configuration, click the  icon to save the configuration.

icon to save the configuration.

The status of the welder displays the weld current and weld voltage in real time as fed back from the welder. The unit of welding current is A, the unit of welding voltage is V.

The welder operates as follows:

Tap Feed: Push button long press triggers to control the wire feeder to feed the wire, button release stops the wire feed;

Welding wire backdrawing: button long press trigger, control wire feeder back to the wire, button release will stop back to the wire;

Protective Gas Detection: Controls the welder gas valve to open, for detecting whether the gas supply is normal.