Welding Settings#

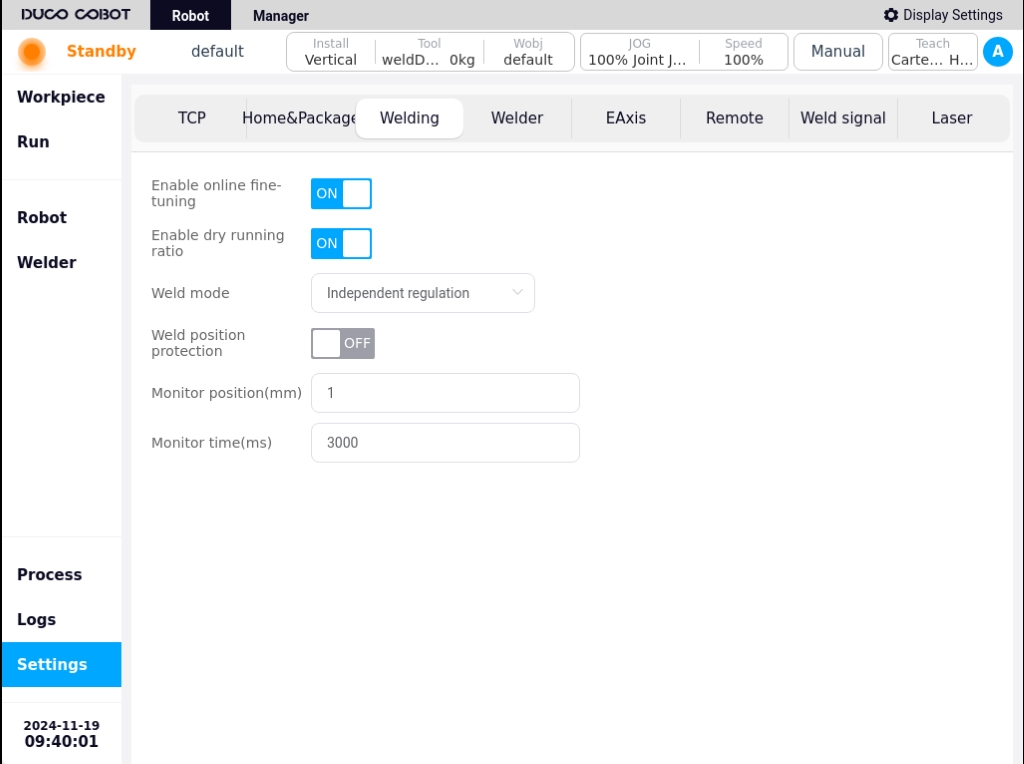

The Weld Settings sub-page is used to set the online trim, weld air run multiplier, weld position protection, and monitor position and monitor time, as shown below.

Enable on-line fine-tuning: Process parameters can be fine-tuned and modified on-line during the welding process.

Enable dry running ratio: When enabled, it allows the robot to run at a multiplier speed when the welder is not enabled, for quick observation of the correct weld trajectory.The multiplier is set in the process motion parameters.

Weld Mode: Options are DC mono, pulse mono, JOB mode, and intermittent welding.

Weld Position Protection: The protection function during welding is based on the principle of real-time monitoring of the end of the robot tool to see if there is any displacement in excess of the monitored displacement. If the end of the robot tool does not produce enough displacement within the set monitoring time, it is judged that the robot is in the same position, and then the welder will be triggered to close the arc command. The purpose of this function is to prevent the robot from having a long welding operation in the same position, in order to prevent the weldment from burning through.

Monitor Displacement(mm): Set the displacement value for monitoring displacement in mm.

Monitor time (ms): The set monitoring time in ms.