Welding Settings#

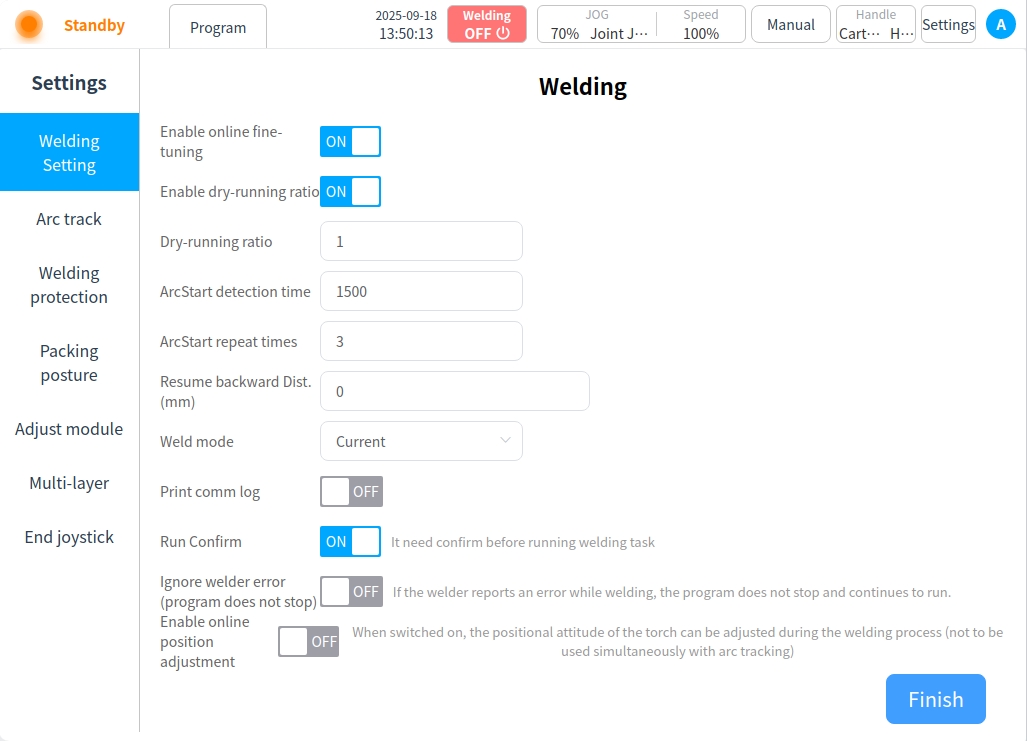

The Weld Settings sub-page is used to set the online fine tuning, weld air-run multiplier, weld mode, print communication log, secondary confirmation of weld execution, ignore welder error report and enable online position adjustment, as shown in the following figure.

Enable on-line fine-tuning: Process parameters can be fine-tuned and modified on-line during the welding process.

Enable dry-running ratio: When the Welding Air Running Multiplier function is enabled, it allows the robot to run at multiplied speeds when the welder is not enabled, for quick observation of the correct weld trajectory.

Dry-running ratio: When the function of receiving the empty running rate is enabled, the empty running rate can be set according to the demand, and the default is 1x speed.

ArcStart detection time: Set the arc start detection time, the default is 1.5 seconds.

ArcStart repeat times: Set the arc repeat number, the default is 3 times.

Resume backward Dist.(mm): After interrupting welding, you can set the re-run setback distance when executing again, and the default is 0mm.

Weld Mode: The welding mode of the welder can be set.

Note

This option sets the welding mode of the welder with immediate effect. For welding tasks in workstation mode, the work mode used is determined by the selected process file.

Print comm log: A weld message is recorded each time a weld job is performed when it is turned on, and is viewed on the log page.

Run Confirm: When enabled, a pop-up box secondary confirmation will be performed when executing a weld task when weld enable is turned on.

Ignore welder error (program does not stop): If the welder reports an error while welding, the program does not stop and continues to run.

Enable online position adjustment: When turned on, the positional attitude of the torch can be adjusted during the welding process (cannot be used at the same time as arc tracking).